Download Wind Turbine Design - Wind Engineering - Lecture Slides and more Slides Environmental Law and Policy in PDF only on Docsity!

Wind Engineering

Module 5.1:

Wind Turbine Design Overview,

Radius, and Airfoils

Recap

- In Module 1, we looked at an overview of the course objectives,

syllabus, and deliverables. We also reviewed history of wind

technology, nomenclature, and case studies.

- In Module 2, we looked at the wind turbine as an actuator disk, and

established the theoretical maximum for power that may be

captured.

- In module 3, we reviewed airfoil aerodynamics, and discussed how

to compute lift and drag coefficients. We also reviewed airfoil

design issues.

- In Module 4, we looked at how wind turbines may be modeled

using blade element theory. We also looked at some commonly

available public domain performance codes.

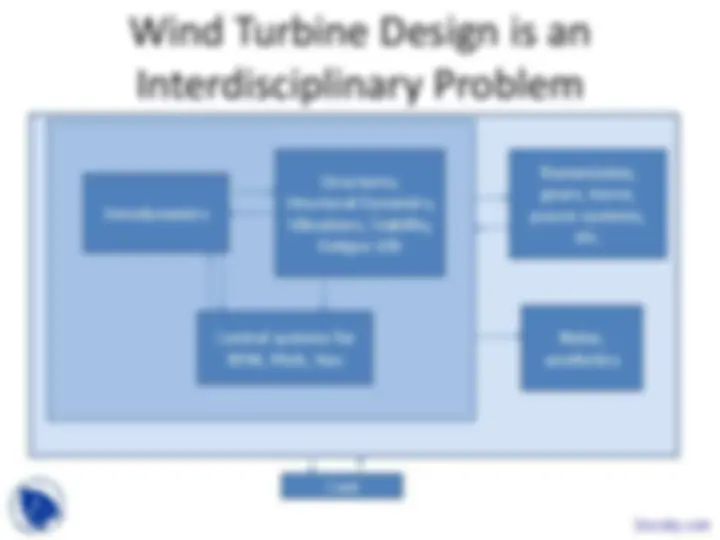

Wind Turbine Design is an

Interdisciplinary Problem

Aerodynamics

Structures, Structural Dynamics, Vibrations, Stability, Fatigue Life

Control systems for RPM, Pitch, Yaw

Transmission, gears, tower, power systems, etc.

Cost

Noise, aesthetics

Parameters to be Chosen

• We need to decide on

– Number of blades

– Blade planform (i.e. how does chord vary with

radius)?

– Blade radius

– Blade twist distribution

– Airfoils

– RPM

– Decisions about variable RPM, variable pitch

• We need to consider cost, noise, vibrations,

fatigue, etc as well.

Some References cited in

NREL/TP-500-

- [1] Harrison, R.; Jenkins, G.; Cost Modeling of Horizontal Axis Wind Turbines. ETSU W/34/00170/REP. University of Sunderland, School of Environment, December 1993

- [2] Griffin, D. A. WindPACT Turbine Design Scaling Studies Technical Area 1 -- Composite Blades for 80- to 120-Meter Rotor; 21 March 2000 - 15 March 2001. NREL/SR-500-29492. Golden, CO: National Renewable Energy Laboratory, April 2001.

- [3] Smith, K. WindPACT Turbine Design Scaling Studies Technical Area 2: Turbine, Rotor and Blade Logistics; 27 March 2000 - 31 December 2000. NREL/SR-500- 29439. Work performed by Global Energy Concepts, LLC, Kirkland, WA. Golden, CO: National Renewable Energy Laboratory, June 2001.

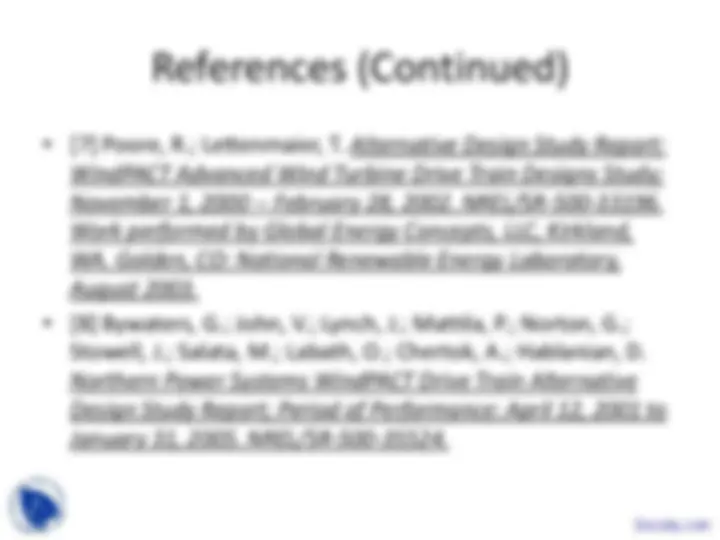

References (Continued)

- [4] WindPACT Turbine Design Scaling Studies Technical Area 3 -- Self-Erecting Tower and Nacelle Feasibility: March 2000 - March 2001. (2001). NREL/SR-500-29493. Work performed by Global Energy Concepts, LLC, Kirkland, WA. Golden, CO: National Renewable Energy Laboratory, May 2001.

- [5] Shafer, D. A.; Strawmyer, K. R.; Conley, R. M.; Guidinger, J. H.; Wilkie, D. C.; Zellman, T. F.; Bernadett, D. W. WindPACT Turbine Design Scaling Studies: Technical Area 4 -- Balance-of-Station Cost; 21 March 2000 - 15 March 2001. NREL/SR-500- 29950. Work performed by Commonwealth Associates, Inc., Jackson, MI. Golden, CO: National Renewable Energy Laboratory, July 2001.

- [6] Malcolm, D. J.; Hansen, A. C. WindPACT Turbine Rotor Design Study: June 2000-- June 2002 (Revised). NREL/SR-500-32495. Work performed by Global Energy Concepts, LLC, Kirkland, WA; and Windward Engineering, Salt Lake City, UT. Golden, CO: National Renewable Energy Laboratory, April 2006 (revised).

Design Approaches

• A parametric sweep may be done using a fast but

reliable software such as WT_PERF or PROPID to

identify best configurations and parametric

combinations.

• One can pose the problem as an optimization problem:

maximize power (MW) or MW-Hr for a range of wind

conditions, subject to constraints such as cost, weight,

fatigue life, etc.

- PropID has an inverse mode that accomplishes this.

• One can use genetic algorithms to combine the best

features of known configurations (gene pool).

- PropGA developed by Philippe Giguère

Which parameters to change?

• Rotor radius affects peak power.

- Recall actuator disk theory says that the power is proportional to disk area.

• Changing the twist changes the angle of attack and

affects lift and drag coefficient.

• Changing the chord affects the axial induction factor,

and to a small extent the tangential induction factor.

- The goal is to make axial induction factor approach the Betz limit.

• Caution: The rotor performance is affected by the

interplay between these variables.

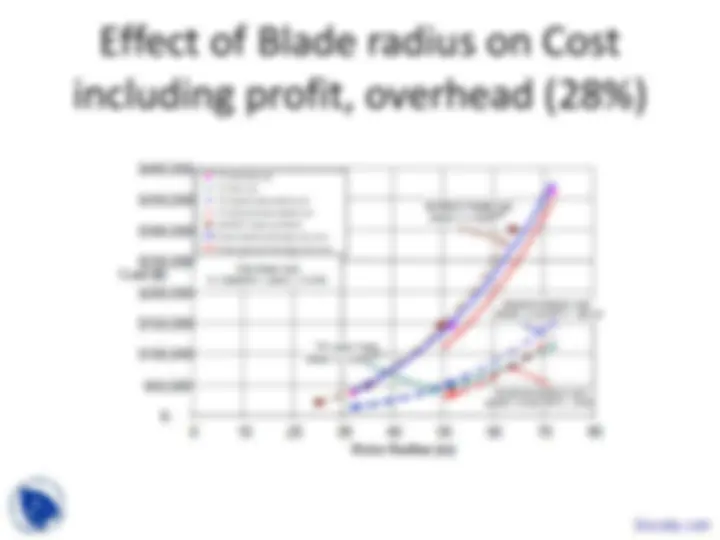

Effect of Blade radius on Cost

including profit, overhead (28%)

Effect of Blade Radius on Tower Mass

Tower Cost = $1.50 per kg

Wind Turbine Airfoils

- Design Perspective

- The environment in which wind turbines operate and their mode of operation not the same as for aircraft - Roughness effects resulting from airborne particles

are important for wind turbines

- Larger airfoil thicknesses needed for wind turbines

- Different environments and modes of operation imply different design requirements

- The airfoils designed for aircraft not optimum for wind turbines

The remaining slides are from a short course on PropID at UIUC Prepared by Jim Tangler:

- Design Philosophy

- Design specially-tailored airfoils for wind turbines

- Design airfoil families with decreasing thickness from

root to tip to accommodate both structural and

aerodynamic needs

- Design different families for different wind turbine size

and rotor rigidity

- Design Criteria for Wind Turbine Airfoils

- Moderate to high thickness ratio t/c

- Rigid rotor: 16%–26% t/c

- Flexible rotor: 11%–21% t/c

- Small wind turbines: 10%-16% t/c

- High lift-to-drag ratio

- Minimal roughness sensitivity

- Weak laminar separation bubbles

- NREL Advanced Airfoil Families

Blade Length Generator Size Thickness Airfoil Family (meters) (kW) Category (root--------------------------------tip)

1-5 2-20 thick S823 S 5-10 20-150 thin S804 S801 S 5-10 20-150 thin S808 S807 S805A S806A 5-10 20-150 thick S821 S819 S 10-15 150-400 thick S815 S814 S809 S 10-15 150-400 thick S815 S814 S812 S 15-25 400-1000 thick S818 S816 S 15-25 400-1000 thick S818 (^) S825 S

Note: Shaded airfoils have been wind tunnel tested.