Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

These are the Lecture Slides of Material Science for Engineers which includes Structure of Wood, Moisture Content, Density of Wood, Mechanical Properties of Wood, Expansion and Contraction of Wood, Concrete Materials, Properties of Concrete etc. Key important points are: Strain Hardening, Annealing, Relationship of Cold Working, Stress-Strain Curve, Strain-Hardening Mechanisms, Texture Strengthening, Residual Stresses, Characteristics of Cold Working, Control of Annealing

Typology: Slides

1 / 56

This page cannot be seen from the preview

Don't miss anything!

Section 7.

Relationship of Cold Working to

the Stress-Strain Curve

Figure 7. Development of strain hardening from the stress- strain diagram

©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning

is a trademark used herein under license.™ (^) Figure 7.3 The true

stress-true strain curves for metals with large and small strain-hardening exponents. Larger degrees of strengthening are obtained for a given strain for the metal with the larger n

Section 7.

Strain-Hardening Mechanisms

Figure 7.5 The Frank-Read source can generate dislocations. (a) A dislocation is pinned at its ends by lattice defects. (b) As the dislocation continues to move, the dislocation bows, eventually bending back on itself. (c) finally the dislocation loop forms, and (d) a new dislocation is created. (e) Electron micrograph of a Frank-Read source (330,000). (Adapted from Brittain, J., ‘‘Climb Sources in Beta Prime- NiAl,’’ Metallurgical Transactions, Vol. 6A, April 1975.)

Section 7.

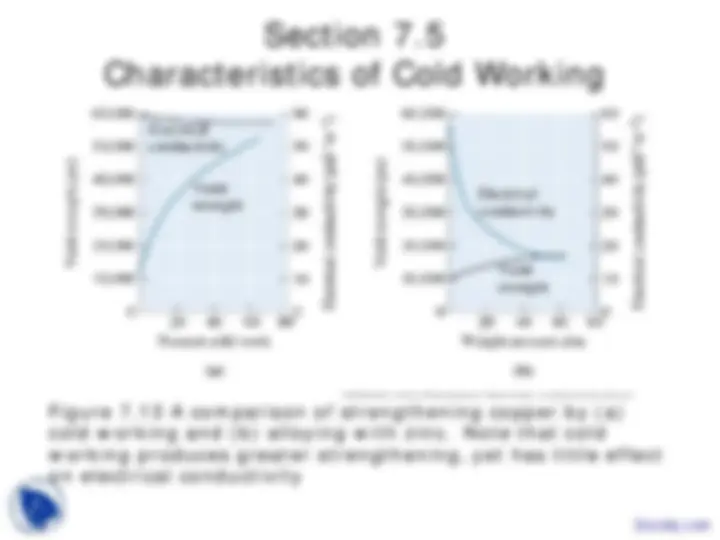

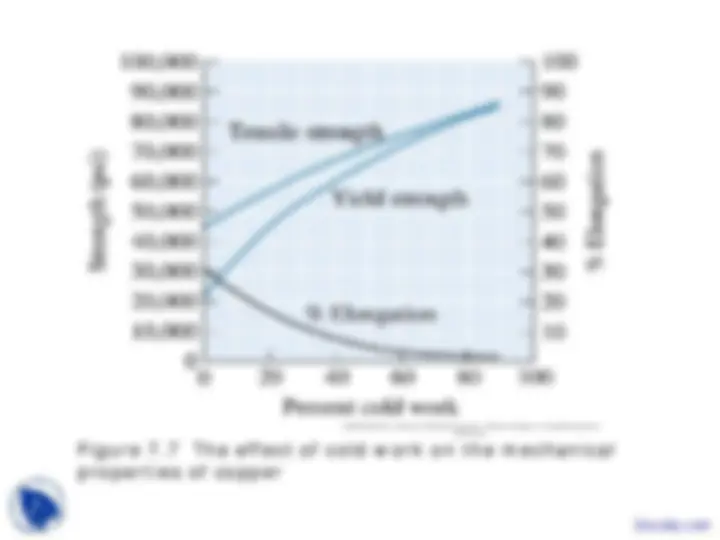

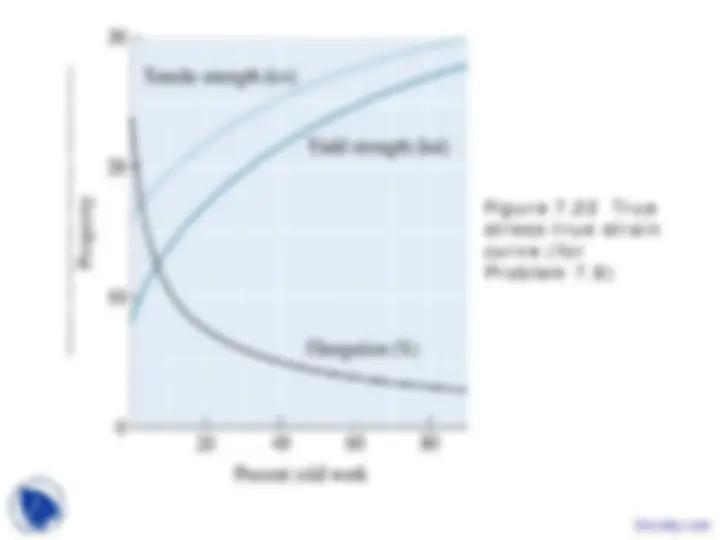

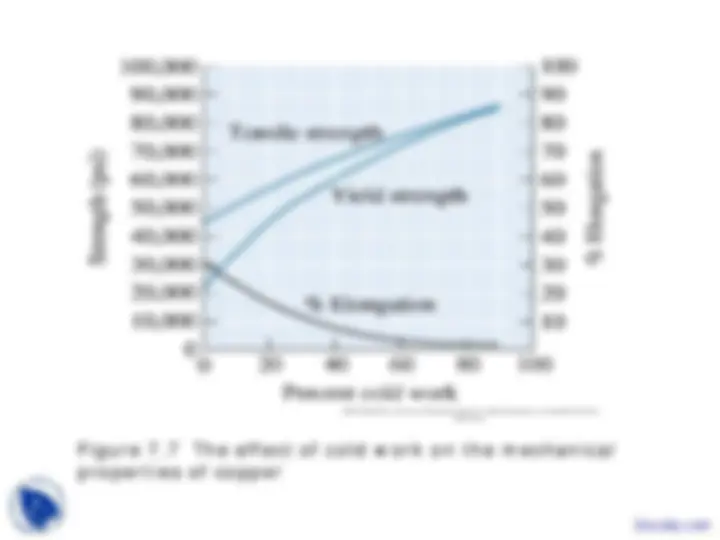

Properties versus Percent Cold Work

©2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learningtrademark used herein under license. ™ is a Figure 7.7 The effect of cold work on the mechanical properties of copper

Example 7.

Cold Working a Copper Plate

Example 7. Design of a Cold Working Process

Section 7.

Microstructure, Texture Strengthening,

and Residual Stresses

Figure 7.9 The fibrous grain structure of a low carbon steel produced by cold working: (a) 10% cold work, (b) 30% cold work, (c) 60% cold work, and (d) 90% cold work (250). (Source: From ASM Handbook Vol. 9, Metallography and Microstructure, (1985) ASM International, Materials Park, OH