Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Main points of this past exam are: Sheave Pitch Diameter, Aid, Curve, Ferrous Material, Actuating Mechanism, Louvre Damper, Return Duct, Deep, Ultimate Tensile, Stress

Typology: Exams

1 / 19

This page cannot be seen from the preview

Don't miss anything!

Answer FIVE questions. All questions carry equal marks.

Examiners: Mr. J.M. Brady Mr. D. Leonard Dr. N. J. Hewitt

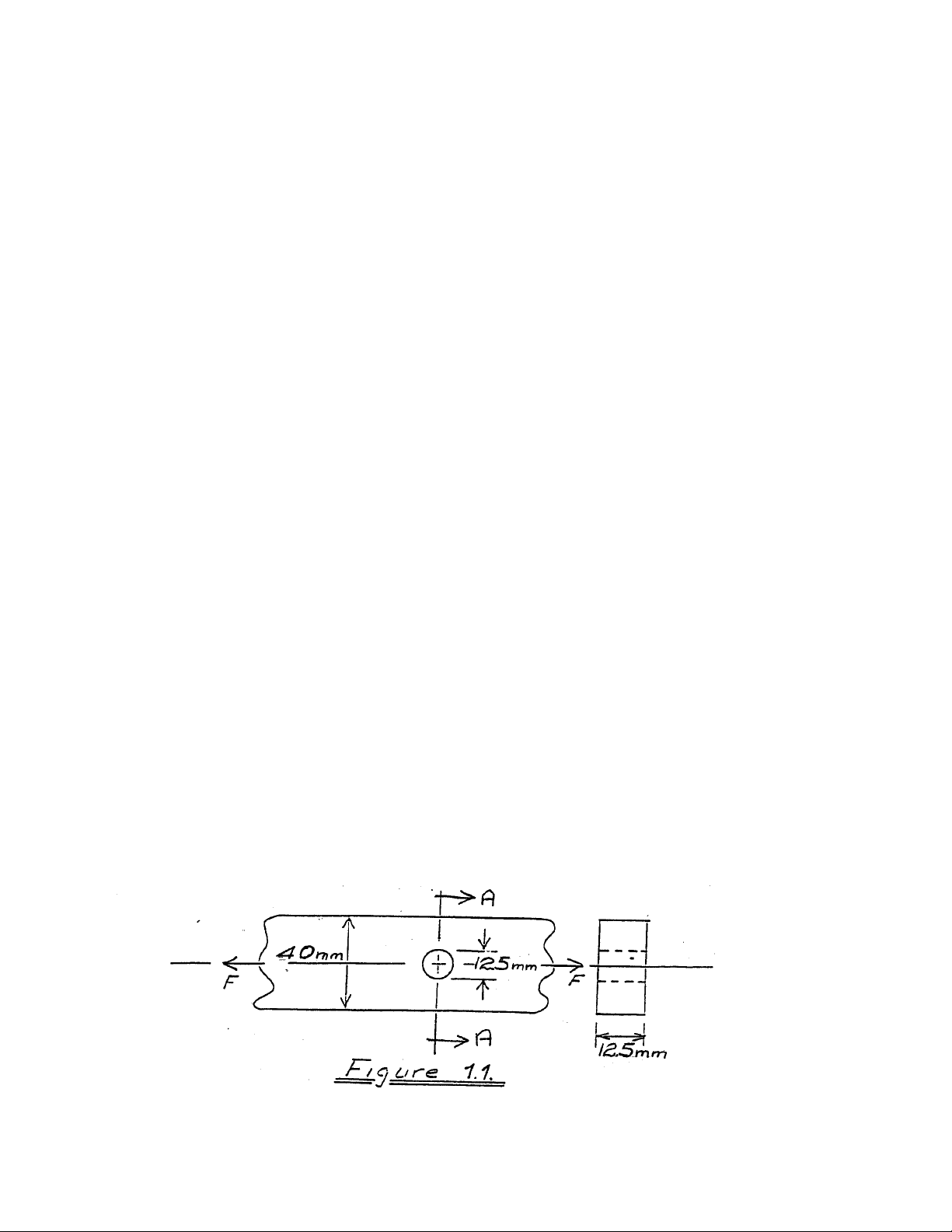

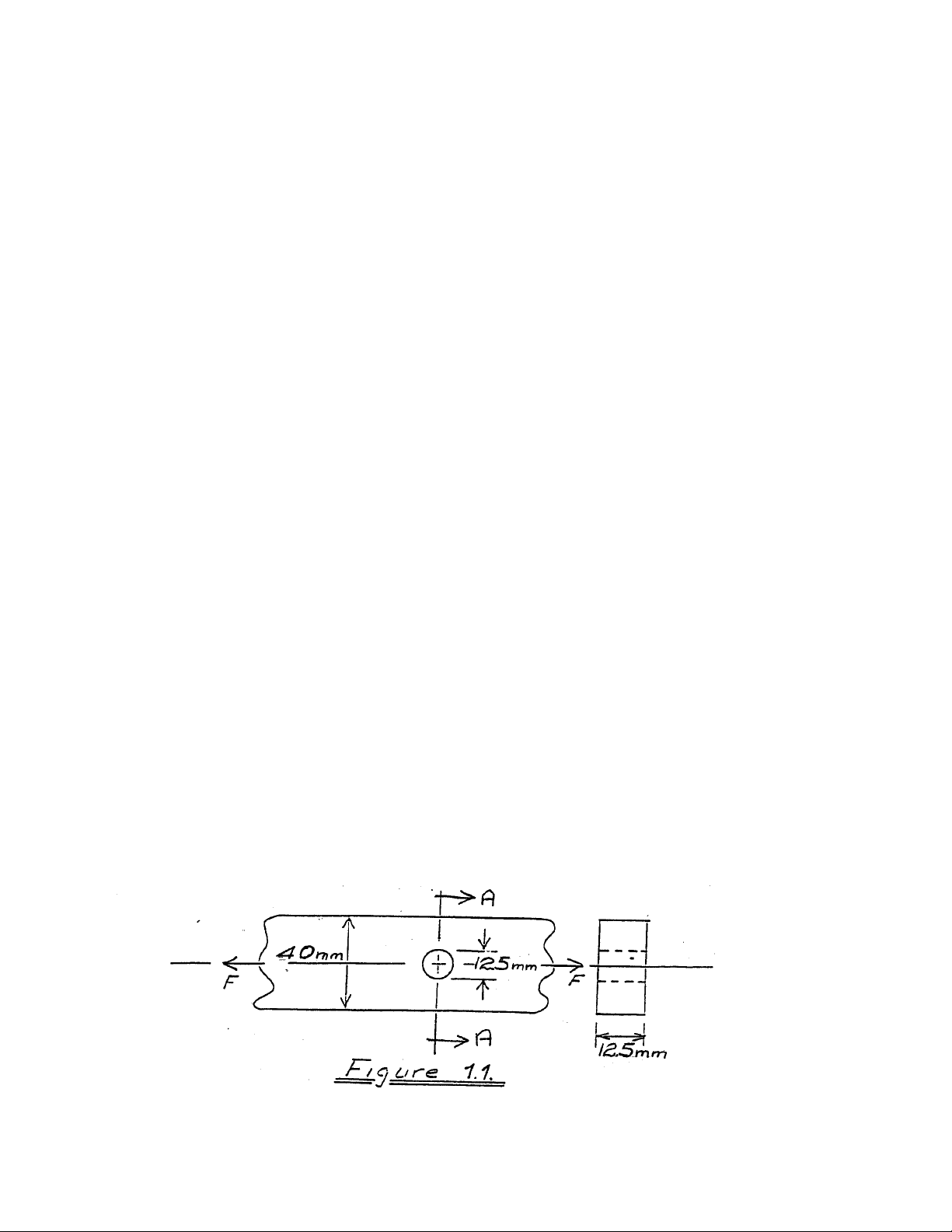

Q1. (a) Explain briefly, with the aid of a sketch, what is an ‘S – N’, or ‘S – Log N’ curve, and indicate the main difference between such a curve for a ferrous material, and for a non- ferrous material. (6 marks) (b) Part of the actuating mechanism of a louvre damper on the return duct of an air conditioning system is to be manufactured from rectangular steel bar, 40 mm deep by 12.5 mm thick, with a hole 12.5 mm diameter drilled centrally, as shown in Fig.1.1 below. The ultimate tensile strength of the steel to be used, Sut = 650 N/mm^2 and the part will have a machined surface. If the actuator has to carry a fully reversed load of 3.0 kN, with a reliability of 99.0%, at an operating temperature of 120°C, calculate: (i) the actual corrected fatigue strength, S (^) e, for this part of the mechanism.(8 marks) (ii) the actual maximum tensile stress in the rod at section A – A. (3 marks) (iii) will the maximum tensile stress at section A – A, result in fatigue failure of the part? (3 marks) Note: Use Fig.1.2 to 1.4 and Tables 1.1 to 1.4 attached.

Q2. The flat machined bar, part of the operating mechanism of lift doors, shown in Fig.2.

Assuming a factor of safety of 3, and 99.9% reliability, calculate the plate thickness for: (i) static loading (5 marks) (ii) fully reversed loading (disregard notch sensitivity, i.e. Kf = Kt ) (7 marks) (iii) repeated loading where Pmax = 80 kN and P (^) min = 0. Use the Soderberg criterion

i.e.

yt a e m

Note: Use Fig.1.2, 2.2 and Tables 1.1 to 1.4 attached.

Q3. (a) Describe, with the aid of simple sketches, the five basic types of loading to which an adhesive joint may be subjected, and indicate under which type of loading the adhesive bond is strongest, and under which it is weakest. (5 marks) (b) Briefly describe three surface pre-treatment procedures for adhesive bonding, in order of effectiveness, referring to any equipment or solvents required. (5 marks) (c) Outline the various advantages and disadvantages of the use of adhesive bonding, compared with traditional joining methods. (5 marks) (d) Name three types of modern adhesives, and outline the main characteristics of each. (5 marks)

Q6. (a) Give the main advantages and disadvantages of Rolling Contact bearings over Journal bearings, and give the circumstances in which each type might be used, illustrating your answer with a sketch graph of the relationship between friction and speed for each of the three main bearing types; journal, roller, and ball. (12 marks) (b) The winding drum of a crane supports a load of 500 kg on the lifting cable. The shaft of the winding drum is 50 mm diameter, and the mass of the drum is 50 kg. If the drum rotates at 80 RPM and is supported by two bearings which carry the shaft at either end of the drum, calculate the basic dynamic load rating for suitable single row ball bearings to give a life of 150,000 hrs with 90% reliability, and give the designation of a suitable bearing. Note: Use Tables 6.1 to 6.3, and Fig.6.1 to 6.4 attached. (8 marks)

Q7. (a) Describe briefly the following types of belt used in belt drives, including a typical application in each case, using sketches to illustrate your answer: (i) Round belt (ii) Flat belt (iii) V-belt (iv) Toothed belt. (8 marks)

(b) Define, in detail, with the aid of sketches where necessary, the following terms when applied to V-belts, when used for power transmission: (i) Belt Pitch length (ii) Sheave Pitch Diameter (iii) Belt contact angle (iv) Centre distance (v) Speed Ratio. (12 marks)