Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

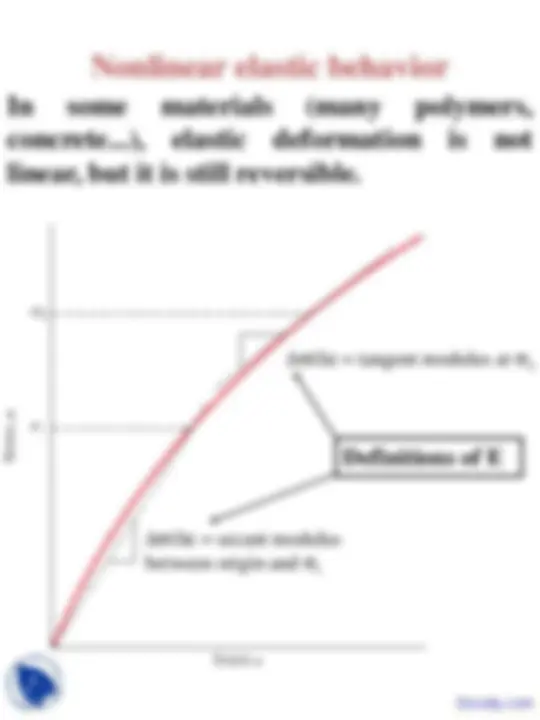

These are the Lecture Slides of Science and Engineering of Materials which includes Point Defects, Types of Defects, Equilibrium Number, Thermal Vibrations, Boltzmann Constant, Regular Lattice Sites, Substitutional Solid Solutions, Composition Conversions etc. Key important points are: Mechanical Properties of Metals, Tension and Compression, Shear and Torsion, Stress-Strain Behavior, Elastic Deformation, Young's Modulus, Nonlinear Elastic Behavior, Potentials and Force

Typology: Slides

1 / 29

This page cannot be seen from the preview

Don't miss anything!

Mechanical Properties of Metals How do metals respond to external loads? Stress and Strain Tension Compression Shear Torsion Elastic deformation

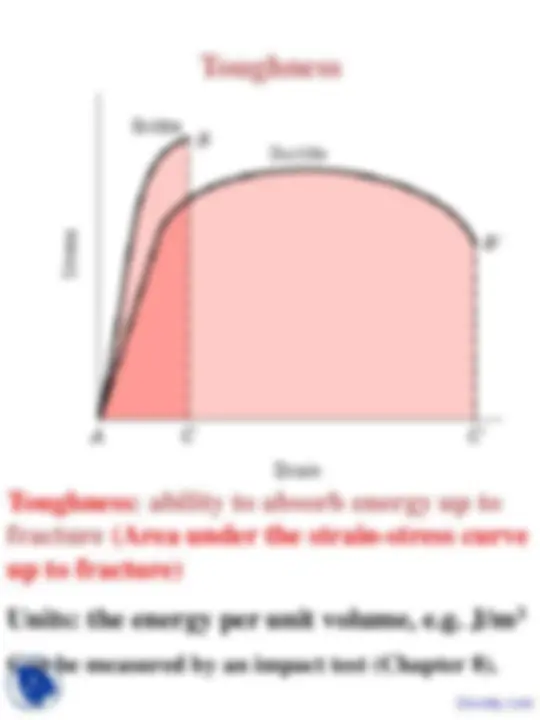

Plastic Deformation Yield Strength Tensile Strength Ductility Toughness Hardness

Chapter 6 Outline

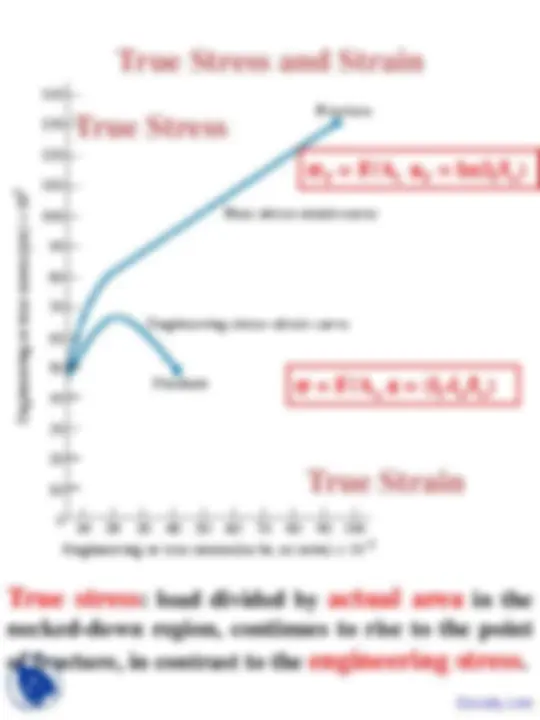

Not tested: true stress-true stain relationships, resilience, details of the different types of hardness tests, variability of material properties

Introduction

Stress,

σ

(MPa)

Strain, ε (mm / mm)

Strain (For Tension and Compression)

Shear and Torsion

F is applied parallel to upper and lower faces each having area A 0.

Shear Torsion

Stress-Strain Behavior (Tension)

Elastic Plastic

Stress

Strain

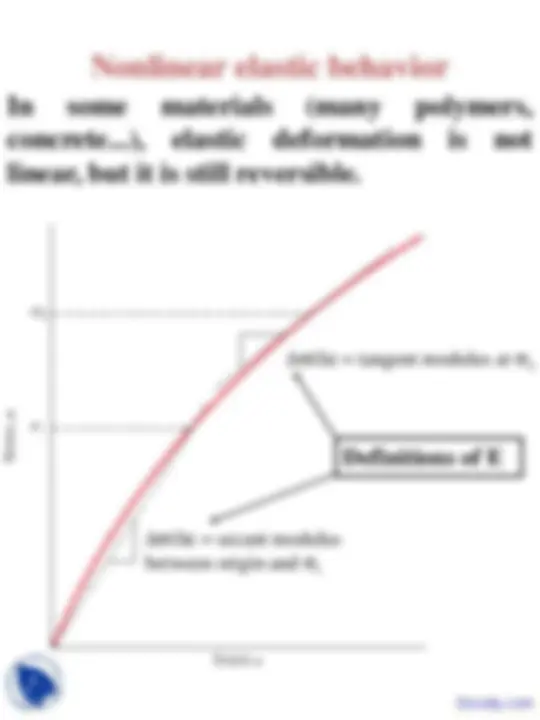

Elastic deformation

Reversible:

( For small strains) Stress removed material returns to original size

Plastic deformation

Irreversible: Stress removed material does not return to original dimensions.

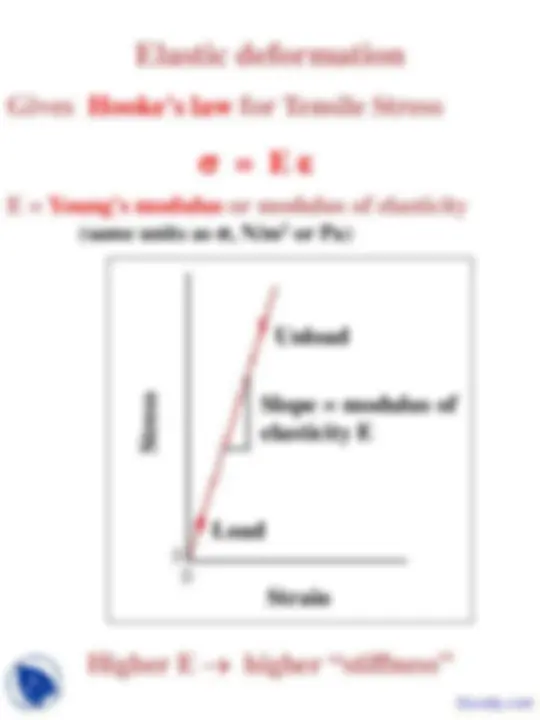

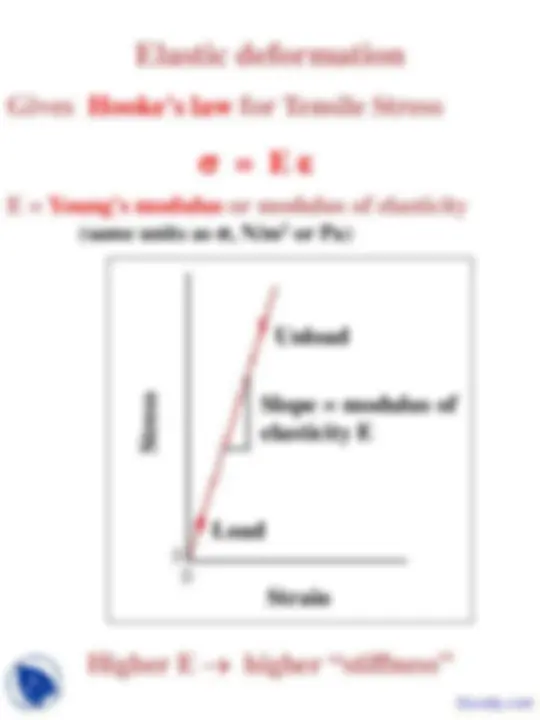

E = Young's modulus or modulus of elasticity (same units as σ, N/m 2 or Pa)

Gives Hooke's law for Tensile Stress

Stress

Strain

Load

Slope = modulus of elasticity E

Unload

Higher E → higher “stiffness”

Chapter 2: Potentials and Force

High modulus

Low modulus

F= (sign) dV/dr

E~ curvature of potential

at equilibrium, r (^0)

Separation, r

Weakly bonded

Strongly bonded

Force, F

Attractive is positive here

(time dependence of elastic deformation)

z

y

z

x ε

ε = − ε

ε ν = −

Theoretical value: for isotropic material: 0.

Maximum value: 0.50, Typical value: 0.24 - 0.

Zo

∆y

τ

Unloaded

Loaded

Shear stress to shear strain:

τ = G γ,

γ = tanθ = ∆y / z (^) o

G is Shear Modulus (Units: N/m 2 )

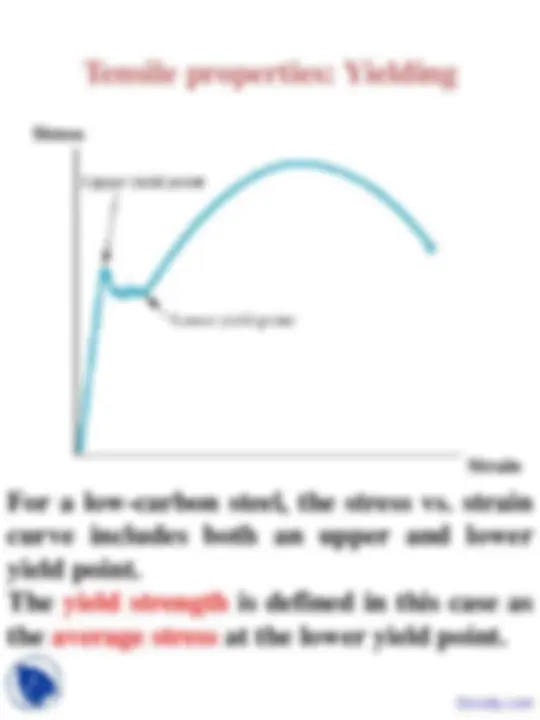

Plastic deformation (Tension)

Plastic deformation:

Elastic Plastic

Stress

Strain Yield strength: σy Permanent strain= 0.

Yield point: P Where strain deviates from being proportional to stress (the proportional limit)

A measure of resistance to plastic deformation

P

σy

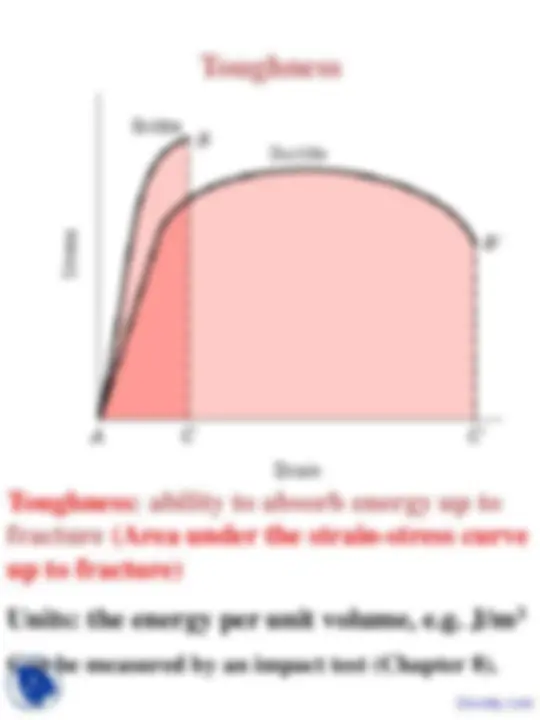

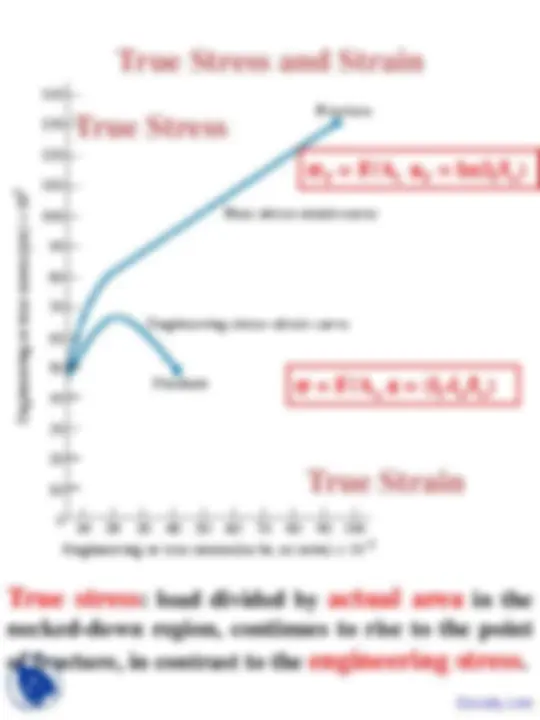

Tensile strength = max. stress (~ 100 - 1000 MPa)

If stress maintained specimen will break

Fracture Strength

Stress, “Necking”

σ

Strain, ε

Yield stress, σy , usually more important than tensile strength. Once yield stress has been passed, structure has deformed beyond acceptable limits.

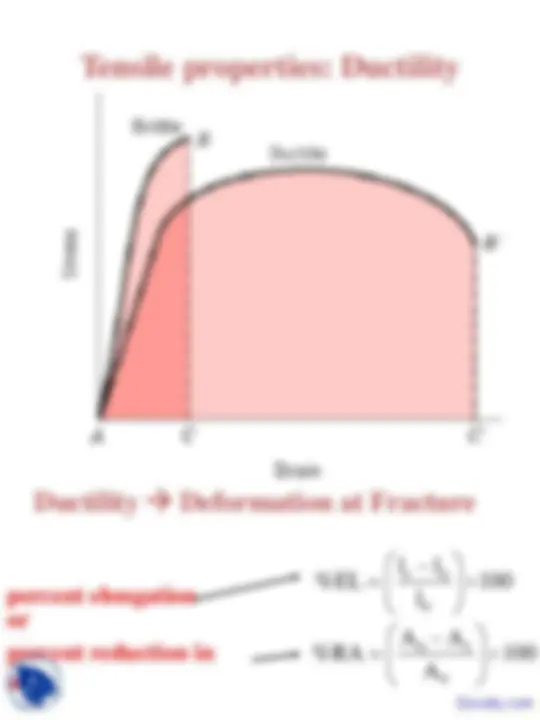

percent elongation or percent reduction in area

Ductility Deformation at Fracture

100 l

%EL l l 0

f (^0) ×

=^ −

100 A

%RA A A 0

0 f ×

=^ −