Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

These are the Lecture Slides of Material Science for Engineers which includes Structure of Wood, Moisture Content, Density of Wood, Mechanical Properties of Wood, Expansion and Contraction of Wood, Concrete Materials, Properties of Concrete etc. Key important points are: Mechanical Properties of Metals, Stress and Strain, Elastic Deformation, Plastic Deformation, Types of Loading, Shear and Torsion, Modulus of Elasticity, Nonlinear Elastic Behavior, Atomic Scale Picture

Typology: Slides

1 / 73

This page cannot be seen from the preview

Don't miss anything!

Section 6. Terminology for Mechanical Properties

Stress - Force or load per unit area of cross-section over which the force or load is acting. Strain - Elongation change in dimension per unit length. Young’s modulus - The slope of the linear part of the stress-strain curve in the elastic region, same as modulus of elasticity. Shear modulus (G) - The slope of the linear part of the shear stress-shear strain curve. Viscosity ( ) - Measure of resistance to flow, defined as the ratio of shear stress to shear strain rate (units Poise or Pa-s). Thixotropic behavior - Materials that show shear thinning and also an apparent viscosity that at a constant rate of shear decreases with time.

Example 6.

Design of a Suspension Rod

An aluminum rod is to withstand an applied force of 45, pounds. To assure a sufficient safety, the maximum allowable stress on the rod is limited to 25,000 psi. The rod must be at least 150 in. long but must deform elastically no more than 0.25 in. when the force is applied. Design an appropriate rod.

Example 6.2 SOLUTION

Section 6. Properties Obtained from the Tensile Test

Elastic limit

Tensile strength, Necking

Hooke’s law

Poisson’s ratio

Modulus of resilience ( Er )

Tensile toughness

Ductility

Example 6. Ductility of an Aluminum Alloy

The aluminum alloy in Example 6.1 has a final length after failure of 2.195 in. and a final diameter of 0.398 in. at the fractured surface. Calculate the ductility of this alloy.

Example 6.4 SOLUTION

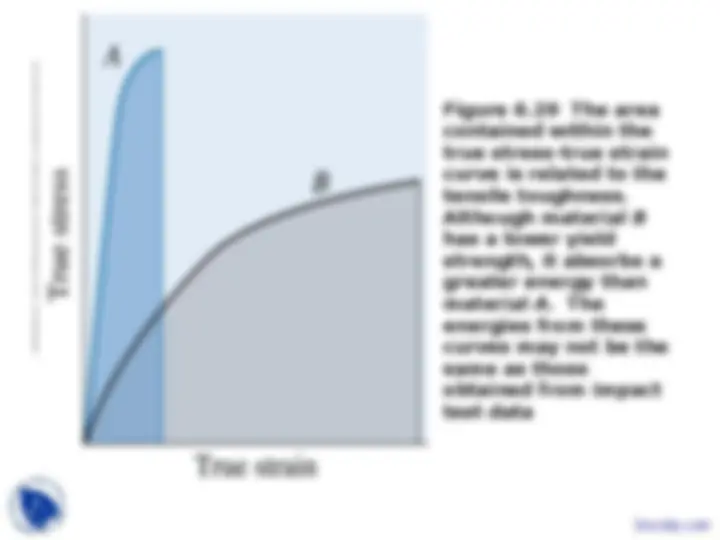

Section 6. True Stress and True Strain

True stress The load divided by the actual cross-sectional area of the specimen at that load.

True strain The strain calculated using actual and not original dimensions, given by εt ln( l / l 0 ).

(c)2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson

Learning

is a trademark used herein under license.™

Figure 6.17^ The relation between the true stress-true strain diagram and engineering stress- engineering strain diagram. The curves are identical to the yield point

Section 6. The Bend Test for Brittle Materials

Bend test - Application of a force to the center of a bar that is supported on each end to determine the resistance of the material to a static or slowly applied load.

Flexural strength or modulus of rupture -The stress required to fracture a specimen in a bend test.

Flexural modulus - The modulus of elasticity calculated from the results of a bend test, giving the slope of the stress-deflection curve.

Example 6. Flexural Strength of Composite Materials

The flexural strength of a composite material reinforced with glass fibers is 45,000 psi and the flexural modulus is 18 106 psi. A sample, which is 0.5 in. wide, 0.375 in. high, and 8 in. long, is supported between two rods 5 in. apart. Determine the force required to fracture the material and the deflection of the sample at fracture, assuming that no plastic deformation occurs.

Example 6.6 SOLUTION

(c)2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learninglicense. ™ is a trademark used herein under

Figure 6.23 Indentors for the Brinell and Rockwell hardness tests

Section 6. Strain Rate Effects and Impact Behavior

Impact test - Measures the ability of a material to absorb the sudden application of a load without breaking.

Impact energy - The energy required to fracture a standard specimen when the load is applied suddenly.

Impact toughness - Energy absorbed by a material, usually notched, during fracture, under the conditions of impact test.

Fracture toughness - The resistance of a material to failure in the presence of a flaw.

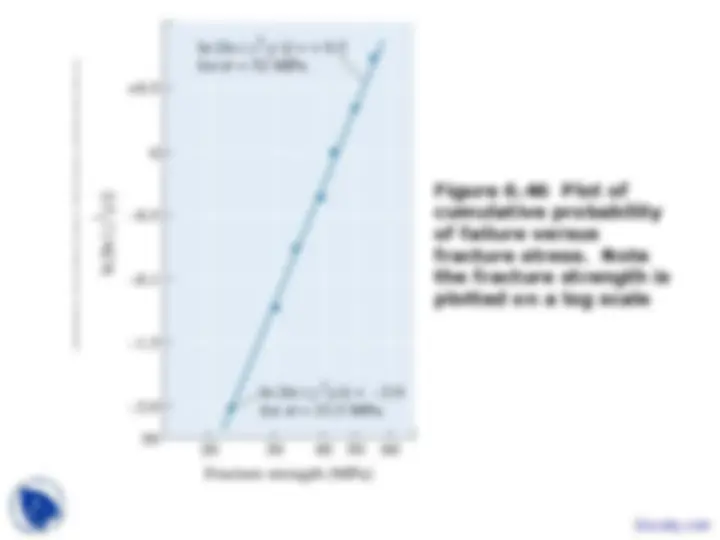

Section 6. Properties Obtained from the Impact Test

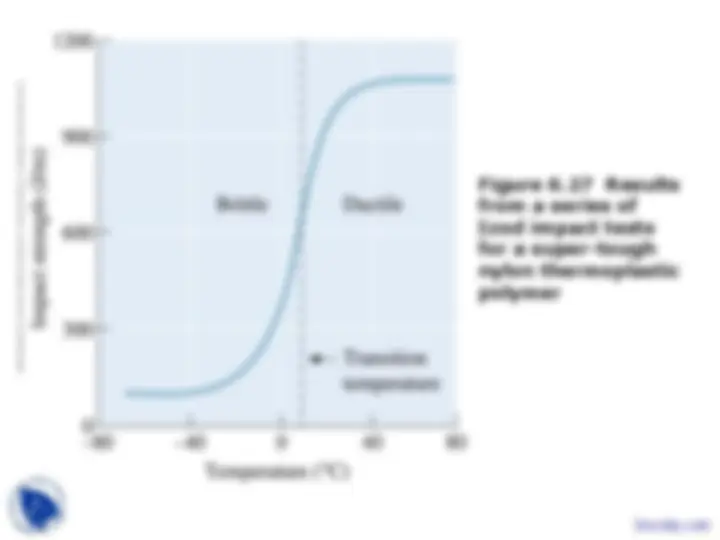

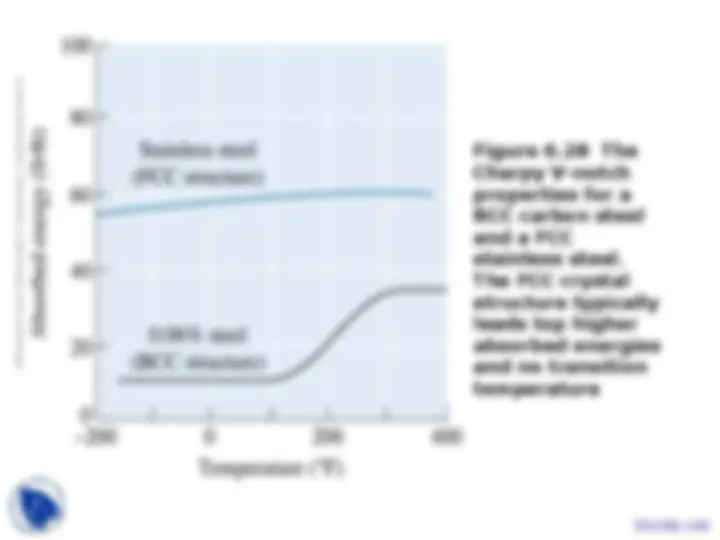

Ductile to brittle transition temperature (DBTT) - The temperature below which a material behaves in a brittle manner in an impact test.

Notch sensitivity - Measures the effect of a notch, scratch, or other imperfection on a material’s properties, such as toughness or fatigue life.

(c)2003 Brooks/Cole, a division of Thomson Learning, Inc. Thomson Learning

is a trademark used herein under license.™ (^) Figure 6.27 Results

from a series of Izod impact tests for a super-tough nylon thermoplastic polymer