Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

This lecture is part of lecture series for Engineering Economics course at M. J. P. Rohilkhand University. It was delivered by Dr. Badrinath Singh to cover following points: Make, Buy, Decisions, Qualitative, Quantitative, Diminishing, Capacity, Cost, Considerations, Continual, Supply

Typology: Slides

1 / 15

This page cannot be seen from the preview

Don't miss anything!

Determination of whether it is more advantageous to make a particular item in house or to buy it from a supplier.

The choice involves both qualitative (such as quality control) and quantitative (such as the relative cost) factors.

The buy side of the decision also is referred to as outsourcing.

Make-or-buy decisions usually arise when a firm that has developed a product or part—or significantly modified a product or part—is having trouble with current suppliers, or has diminishing capacity or changing demand.

Issues like government regulation, competing firms, and market trends all have a strategic impact on the make-or- buy decision.

Cost considerations (less expensive to make the part)

Desire to integrate plant operations

Productive use of excess capacity to help absorb fixed overhead.

Need to exert direct control over production and/or better quality Design secrecy is required to protect proprietary technology

Unreliable suppliers or No competent suppliers

Desire to maintain a stable workforce (in periods of declining sales) Quantity too small to interest a supplier

Control of lead time, transportation, and warehousing costs

Greater assurance of continual supply

Provision of a second source Political, social or environmental reasons (union pressure)

Emotion (e.g., pride)

Lack of expertise

Suppliers' research and specialized know-how exceeds that

of the buyer

cost considerations (less expensive to buy the item)

Small-volume requirements

Limited production facilities or insufficient capacity

Desire to maintain a multiple-source policy

Indirect managerial control considerations

Procurement and inventory considerations

Brand preference

Item not essential to the firm's strategy

Purchase price of the part

Transportation costs

Receiving and inspection costs

Incremental purchasing costs

Any follow-on costs related to quality or service

Quantitative factors deal with cost. The quantitative effects of the make-or-buy decision are best seen through the Relevant Cost Approach.

For example, assume a firm has prepared the following cost estimates for the manufacture of a subassembly component based on an annual production of 8000 units:

The supplier has offered the subassembly at a price of $ each. Two-thirds of fixed factory overhead, which represents executive salaries, rent, depreciation, and taxes, continue regardless of the decision. Should the company buy or make?

Manufacturing model

2

2 0 c (1 / )

C D Q C r k

0 2 2

( ) 2

c

DC Q TC DP C k r Q k

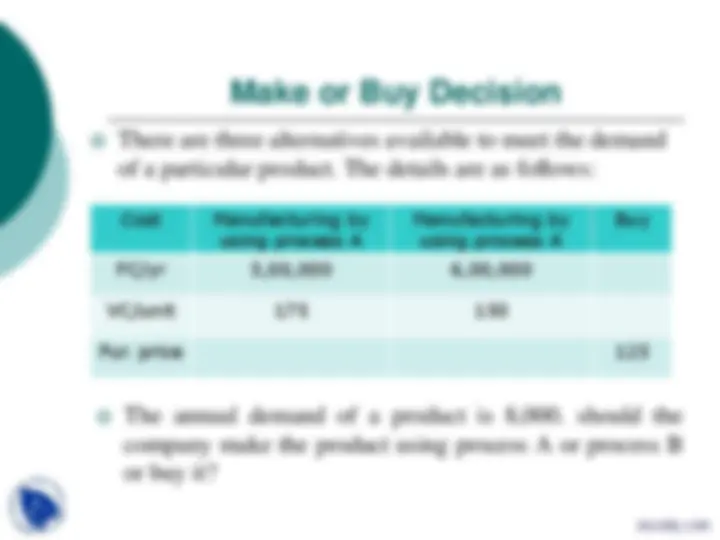

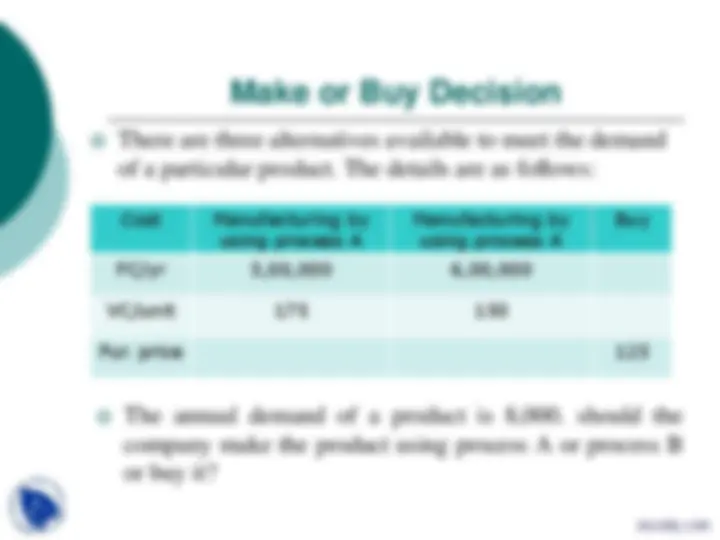

An item has yearly demand of 2000 units. The different costs in respect of make and buy are as follows. Determine the best option.

Buy Make P = Item cost/unit 8.00 5. C 0 = Procurement cost/order cost 120 C 0 = Set up cost (for making) 60 Cc = Annual carrying cost 1.60 1. K = Production rate 8000 units

Break-even point (BEP) is the point at which cost or

expenses and revenue are equal: there is no net loss or gain. The main objective of break-even analysis is to find the cut-off production volume from where a firm will make profit.

cos / cos /

FC BEP Selling t unit Variable t unit

A manufacturer of TV buys TV cabinet at Rs. 500 each.

In case the company makes it within the factory,

the fixed cost is Rs.400, 000/-

variable cost is Rs. 300 per cabinet.

Should the manufacturer make or buy the cabinet if the

demand is 1,500 TV cabinets?