Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

An in-depth look into prestressed concrete, its advantages and disadvantages compared to non-prestressed concrete, and the analysis of rectangular prestressed members. formulas and examples for determining the location of the neutral axis, prestress eccentricity, moment of inertia, stresses during prestressing, and stresses during service loads.

What you will learn

Typology: Study Guides, Projects, Research

1 / 11

This page cannot be seen from the preview

Don't miss anything!

Prestressed concrete refers to concrete that has applied stresses induced into the member. Typically, wires or “tendons” are stretched and then blocked at the ends creating compressive stresses throughout the member’s entire cross- section. Most Prestressed concrete is precast in a plant.

Advantages of Prestressed concrete vs. non-Prestressed concrete:

Disadvantages of Prestressed concrete vs. non-Prestressed concrete:

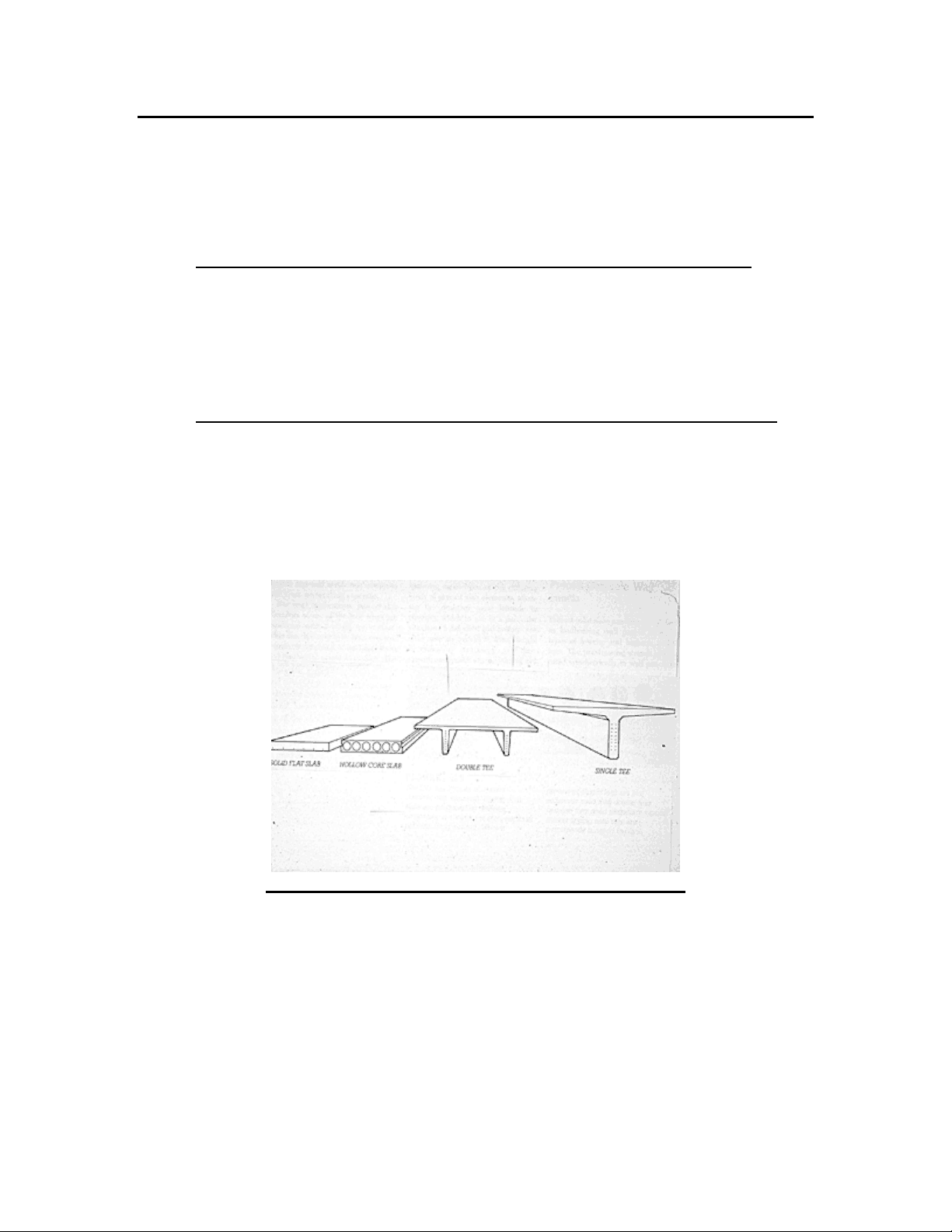

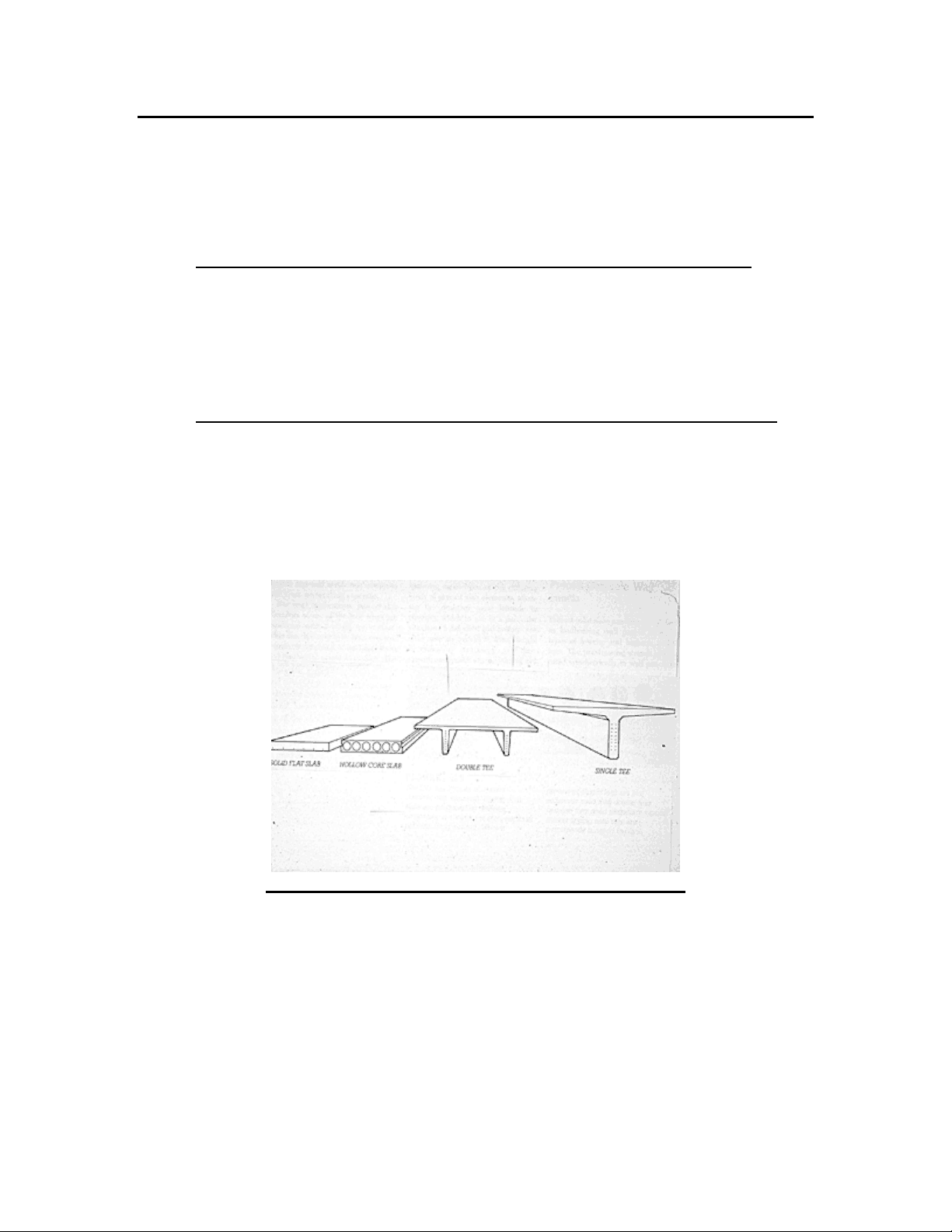

Typical Precast Prestressed concrete members

Pre-Tensioned Prestressed Concrete:

Pre-tensioned concrete is almost always done in a precast plant. A pre- tensioned Prestressed concrete member is cast in a preformed casting bed. The BONDED wires (tendons) are tensioned prior to the concrete hardening. After the concrete hardens to approximately 75% of the specified compressive strength f’c, the tendons are released and axial compressive load is then transmitted to the cross-section of the member.

“Dead” end “Live” end

Tendons tensioned between bulkheads Prestress force Ps Casting bed

Tendons anchored at “Live” end and “Dead” end

Fresh concrete placed in bed

Tendons released at “Live” end and “Dead” end creating an axial force along length of precast member

Prestress force Ps

Hardened concrete

a = f b

A f

c

ps ps

dp h

b

yt

yb e

Aps

Rectangular Prestressed Beam

GIVEN: The rectangular prestressed concrete beam as shown below. Use the following:

REQUIRED:

yt

yb e

Rectangular Prestressed Beam Aps = 0.459 in 2

Step 2 – Determine the moment of inertia about the neutral axis, Ig:

Ig = 2

3 2 ( ) 12 2

nA e h bh y bh t ⎟ + ps ⎠

3 2 ( 3. 30 )( 6. 87 ") 2

⎟ + in ⎠

= 4860 in^4 + 3.0 in^4 + 155.7 in^4

Ig = 5018.7 in^4

Step 3 – Determine the stresses during prestressing:

f = g

s g

s I

Pey A

where: Ps = prestress force = 70%(f (^) pu )(Aps ) = 0.70(270 KSI)(0.459 in 2 ) = 86.8 KIPS

y = yt for tensile stresses at top of beam = y (^) b for compressive stresses at bottom of beam

a) Check stresses at TOP of beam:

f (^) top = stress at top of beam

g

s t g

s I

Pey A

in

x

f (^) top = 0.60 KSI Tension

b) Check stresses at BOTTOM of beam:

f (^) bottom = stress at bottom of beam

g

s b g

s I

Pey A

in

x

f (^) bottom = -1.53 KSI Compression

Step 4 – Determine the stresses during initial applied service beam weight:

f = g

beam I

M ( y ) ±

where: M (^) beam = maximum unfactored moment due to beam wt.

wbeam ( L )^2

= 11,374 Lb-Ft = 11.4 KIP-FT

y = yt for compression in^ top = yb for tension in bottom

a) Check stresses at TOP:

f (^) top = g

beam t I

M ( y ) −

in

KIP − FT ft −

f (^) top = -0.25 KSI Compression

b) Check stresses at BOTTOM:

f (^) bottom = g

DLLL b I

M (^) + ( y )

in

KIP − FT ft

f (^) bottom = 2.44 KSI Tension

Step 6 – Determine the final stresses due to all service loads and prestressing:

Step 7 – Determine the maximum actual factored moment on the beam M (^) max:

M (^) max = 8

w L^2 u

wu = 1.2D + 1.6L = 1.2(400 PLF + 188 PLF) + 1.6(1500 PLF) = 3106 PLF = 3.1 KLF

M (^) max = 8

M (^) max = 188 KIP-FT

Initial Prestress

-0.48C +1.08T -0.25C^ +0.35T -2.51C^ -2.16C

-0.48C -1.05C +0.24T -1.29C +2.44T +1.15T

g

s A

g

s I

Beam Wt. Transfer DL + LL Final

NOTE: All stresses shown have units of KSI

ACI dictates the following maximum permissible stresses at service loads:

a) Compression = 0.60f’ (^) c b) Tension = 6 f ' c

Step 8 – Determine the factored usable moment capacity Mu of the beam:

M (^) u = 0.9Aps f (^) ps (dp - 2

a )

where:

fps = (^) ⎟⎟ ⎠

c

pu p

p pu (^) f

f f '

1

f (^) pu = ultimate tensile strength of prestressing tendon = 270 KSI

γp = factor based on the type of prestressing steel = 0.40 for ordinary wire strand

β1 = 0.80 for concrete f’c = 5000 PSI

ρp = p

ps bd

f (^) ps = (^) ⎟⎟ ⎠

a = f b

A f

c

ps ps

in KSI

M (^) u = 0.9Aps f (^) ps (dp - 2

a )

= 0.9(0.453 in^2 )(249.4 KSI)(16” - 2

= 1492 Kip-In

M (^) u = 124.3 KIP-FT < M (^) max = 188 KIP-FT → NOT ACCEPTABLE