Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

An investigation on the correlation between Schmidt hammer readings and concrete properties such as compressive strength, modulus of elasticity, and velocity. The study involved testing concrete specimens with different cement factors and aggregate types. The results showed that hammer readings could be used as an indicator of concrete quality and strength, with some variations depending on surface moisture and hammer position.

What you will learn

Typology: Lecture notes

1 / 29

This page cannot be seen from the preview

Don't miss anything!

45

S. Army Engineer Waterways Experiment Station C O R P S O F E N G IN E E R S Vicksburg, Mississippi

LIBRARY

MAY 24 1968

Bureau of Reclamation Denver, Colorado

Miscellaneous Papers art information of considéra but not of a scope suffit Technical Reports or L are reproduced in limit copy to an

The tests described, in this paper were conducted as a part of Item CW 600, General Concrete Research, of the Corps of Engineers Civil Works Investigation program. The tests were conducted at the Waterways Experi ment Station under the general supervision of Mr. T. B. Kennedy, Chief, Concrete Division, and Messrs. J. M. Polatty and B. Mather, Chiefs of the Concrete and Special Investigation Branches, respectively. Messrs. W. 0. Tynes, E. E. McCoy, Jr., and R. A. Bendinelli actively participated in the investigations. This report was prepared by Mr. C. H. Willetts.

CONTENTS P a g e P R E F A C E ............................................. H i SUMMARY....................................................................................................................................................... ........ PART I : BACKGROUND, PURPOSE, AND S C O P E ........................................................................ 1 B a c k g r o u n d .............................................................................................................................. 1

PART I I : MATERIALS, CONCRETEMIXTURES, SPECIMENS, AND TESTS.... 3 M a t e r i a l s ................................................................................................................................... 3 C o n c r e t e M ix t u r e s a n d S p e c im e n s ............................................................................ 3 T e s t s ............................................................................................................................................. A PART I I I : DISCUSSION AND CON CLU SION S............................................................................ 6 D i s c u s s i o n .............................................................................................................................. 6 C o n c lu s io n s .............................................................................................................................. 8 REFERENCES ............................................................................................................................................. 9

PLATES 1 - h

Background

**1. A simple, compact instrument or tool that can measure nonde- structively, and with adequate accuracy and reliability, a property of con crete that may be correlated with results obtained from some accepted stand ard of measurement of that quality, such as compressive or flexural strength, modulus of elasticity, or pulse velocity, has long been needed in concrete construction work. Numerous instruments and techniques have been developed, but none have been entirely satisfactory. One of these test methods that has survived is known as the "hammer test" or "drum test." In this test a concrete surface is struck smartly with a common hammer, and the quality of the concrete is judged by the smartness of rebound and the tone of the sound resulting from the blow. Such classification terms as "drummy" or "sharp" are outgrowths of such a method of testing.

done in order to prove that a definite range of hammer readings can he cor related with a definite range of the property or quality for which the con crete is being tested. Zoldners'^ work in 1 956 was comprehensive enough to permit the following statement, "The Schmidt hammer provides a simple, in expensive method of nondestructive testing of concrete in place. It cannot substitute for standard methods of compressive tests, but its accuracy is sufficient to determine probable strength limits of the concrete in the structure and detect low-strength batches provided it is calibrated properly O and used competently." Peterson and Stoll state that "the use of the con crete test hammer may save much of the cost and time involved in making of regular compressive strength tests if these tests are being made solely as a check on the constancy of quality of concrete." Two of the conclusions reached by Williams0 were that "concrete specimens from the same aggregate source, tested at the same age, and having nearly the same curing and stor age conditions will produce good correlation between rebound numbers and compressive strength ..." and "when many variables are considered, it would be erroneous to use the curve which was supplied with the instrument (or any modification of the curve) to predict the compressive strength of all con- crete." Mather concluded from tests conducted on precast concrete units in Iceland that "rebound numbers determined on Schokbeton building units are indicative of concrete of high compressive strength." Purpose and Scope

k

**room where they remained for a period of days.

10. After the panels had been tested, as described subsequently, cores, prisms, and beams were cut from them for additional tests. These test specimens are described in the following subparagraphs. a. Ten 6 - by 12-in. cores were extracted from panels 1, 2, and 3, and 20 from panel 4. Half of the cores from each panel were placed in the curing room for an additional 7 days of moist curing; the other half were air-dried in the labora tory for the same length of time. b. A 60- by 12- by 6 -in. section was sawed from one side of each panel and cut into five 12 - by 12 - by 6 -in. prisms. Three of the five prisms were placed in limewater for seven days, and two were air-dried in the laboratory for seven days. c. The other 60- by 12- by 6 -in. side of each panel was sawed — into four 6 - by 6 - by 60 -in. beams, two of which were soaked in limewater and two were air-dried for a period of seven days.

Tests

Panels

11. Twenty-eight days after casting, each 1-ft square area on both sides of each panel was tested 30 times with the Schmidt hammer, 15 times with the panel in a vertical position and the hammer horizontal and 15 times with the panel in a horizontal position and the hammer vertical,

5

making a total of 1200 individual readings for each panel. The hammer blows were carefully randomized over the 1-ft squares. All tests were made in accordance with the manufacturer's recommendations. The average Schmidt- hammer readings for each square of each panel are listed in tables 2-5. Cylinders

**12. All cylinders were tested for compressive strength and modulus of elasticity at 28 days age. Results of these tests are found in tables 2-5- Cores

7

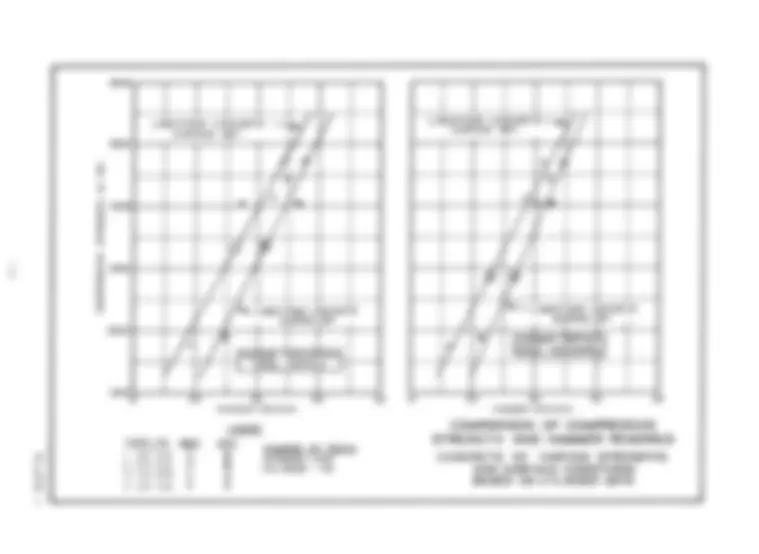

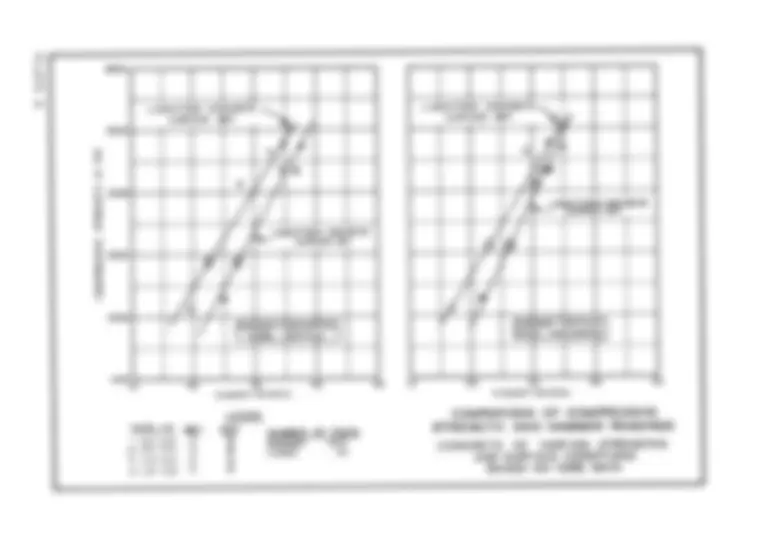

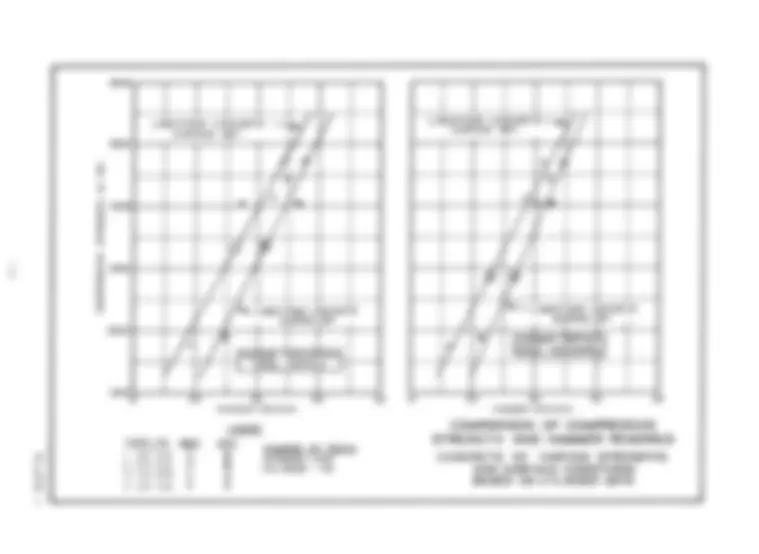

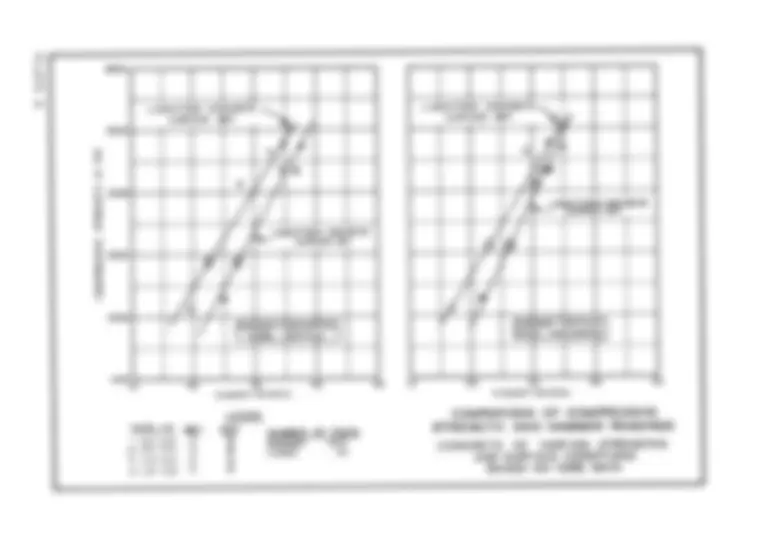

providing the surface upon which the tests are conducted does not change from wet to dry or vice versa. The influence exerted on the hammer read ings by changes in surface condition is also shown in plates 1 and 2.

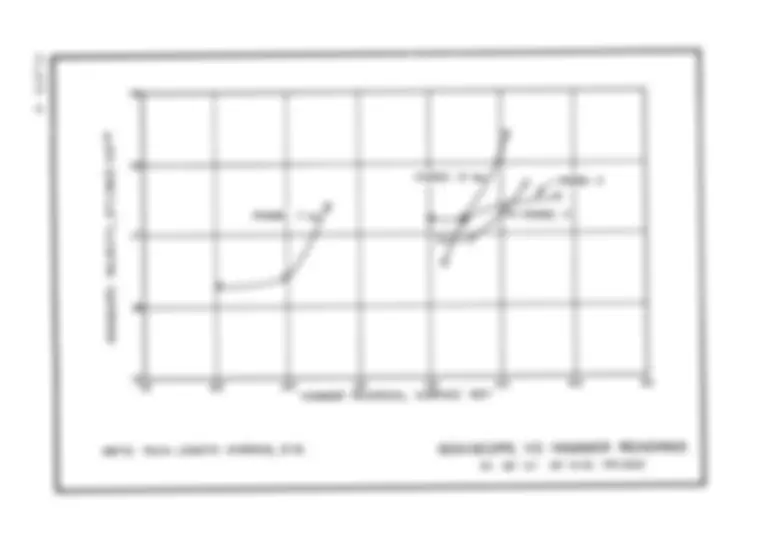

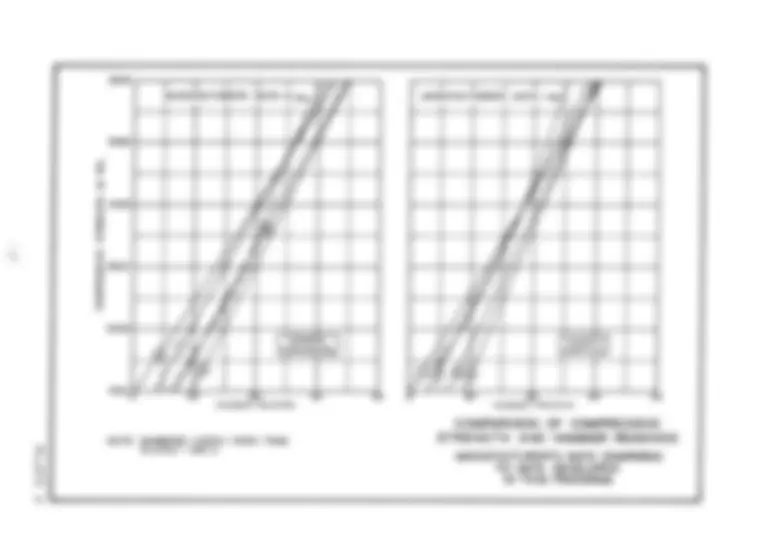

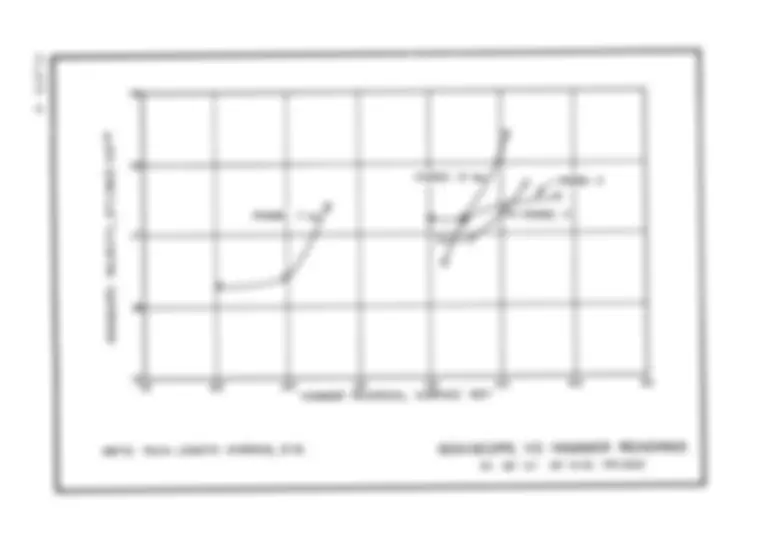

readings and soniscope velocity determinations except that as the hammer readings become progressively larger, the soniscope may or may not indicate a change in the velocity of the transmitted impulse. No relationship is indicated by this limited study between cement content, compressive strength, sound velocity, and hammer readings. Neither are the soniscope determinations nor the hammer-rebound readings influenced by any super imposed loads. 23* Plate 3 shows the relative position of the data developed by this limited series of tests with respect to the data furnished by the manufacturer regarding the correction curve to be used if the hammer is held horizontally or vertically during the test. The data indicate that with the hammer in a horizontal position, a difference of approximately 15C0 psi in compressive strength may result in tests of the same concrete depending on whether the surface of the concrete is wet or dry. The manu facturer's data do not indicate that this might occur. In the cases where the hammer is held vertically and used on wet surfaces, the manufacturer's data do not vary greatly over-all from the data developed by this series of tests except in the very high compressive strength range. However, such is not the case where the hammer is held vertically and used on dry surfaces.

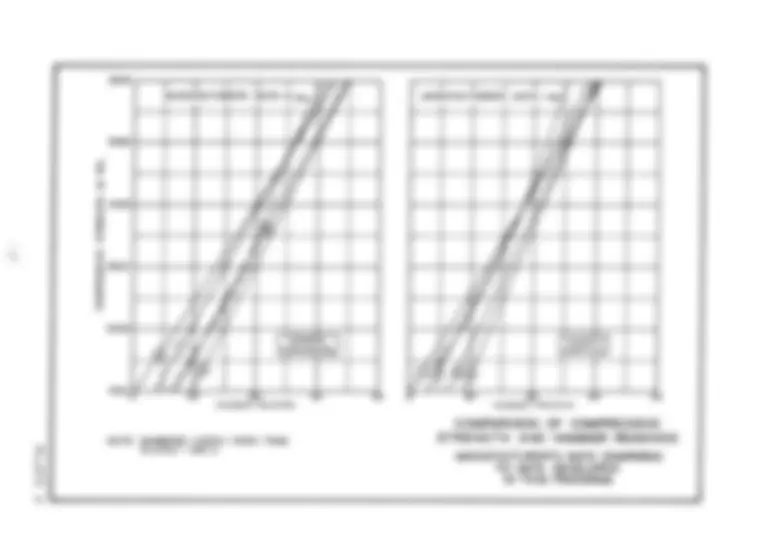

beams cut from each panel indicated the same general trend as did the cores

8

and cylinders: increased hammer readings with increased strength, lower readings on wet surfaces than on dry surfaces. Readings were taken only with hammer held in a vertical position. As stated earlier^ no readings were taken on beams cut from panel 2. Readings obtained on the beams from panel ^ (traprock coarse aggregate, natural silica sand, and a cement factor of 5.0 bags per cu yd) agree with the cylinder data in that they are higher than those from panel 1 (cement factor of 3.5 tags per cu yd and limestone aggregate) and are lower than panel 3 (cement factor of 6.5 bags per cu yd and limestone aggregate). The test data for the beams are given

in tables 2-5-

Conclusions

25. From the data derived in this series of tests, it may be stated that: a. The hammer-rebound readings will increase with an increase — in strength of the concrete irrespective of hammer position (horizontal or vertical) or surface condition of the concrete. b. Hammer readings taken on dry concrete surfaces will be gen- — erally higher than readings taken on wet surfaces. c. Hammer readings taken with the hammer held in a horizontal ~ position are generally higher than those obtained with the hammer in a vertical position. d. Hammer readings are not influenced directly by aggregate specific gravity. e. Hammer readings are influenced more by surface moisture than by hammer position. f. Hammer readings could not be correlated with sound velocity — test data except in the most general terms. g. Hammer readings are not influenced by imposed loads other than those necessary to secure the specimen firmly when the hammer is used. h. Impact rebound hammers should be checked and calibrated — against each and every type of concrete on which they are to be used. Curves or data developed by these tests should be used instead of the manufacturer's data which is con tained in an instruction booklet (furnished with each hammer) that contains graphs derived from a statistical analysis of the general data available on hammer performance.

Table 1 Aggregate and Concrete Mixture Data

Physical Property or Mixture Component

______________ Panel 1 ___ 2 3^4

Coarse aggregate (^) o .4 0 .4 0 .4 (^) 1.

Slump, in. (^) 2 - 1 / b 2-1/4 (^) 2 - 1/4 2-I/ Bleeding, (^) 7.3 1.6 (^) 1.6 (^) 6.

Actual unit wt, lb/cu ft (^) 1^5.6 (^) 147.1 (^) 145-9 151. Air content, $ (^) 5.3 4 .8 5-2 (^) 5- Sand/aggregate ratio, c/o (^) h i (^) 35 34 42 Theo. cement factor, b/cu yd (^) 3-7 5.3 6.85 (^) 5. Actual cement factor, b/cu yd (^) 3.51 5.05 6 .4 9 (^) 5. W/C ratio, gal/bag (^) 8.1 (^) 5 .7 4 .8 (^) 5. 5 w/c ratio by wt (^) 0.72 (^) 0.50 0.43 (^) 0.

Cement (^) 329.5 474.7 610.I (^) 472.

No. ^ to 3 /^-in. (^) 1081.3 (^) II52.9 1101.4 1103. 3 /A-- to l-l/ 2 -in. (^) 918.0 978.7 (^) 935-8 (^) 955. Water (^) 236.5 239.7 259.6 (^) 230. Total (^) 3930.8 (^) 3972.7 3938.2 (^) 4098.

*** Panels** 1 , 2 , and 3 contained limestone fine and coarse aggregates, panel 4 contained natural fine and traprock coarse aggregate.

Table 2 Summary of Hammer Rebound Readings and Strength, Modulus of Elasticity, and Velocity Data Obtained from Hardened Concrete Panel 1 Concrete Mixture: Limestone Fine and Coarse Aggregate, 3»5 Bags Cement/cu yd Cylinder Data Core Data Panel Rebound Readings* 20 -day Compr 35 -day Compr Cone Hammer Surf. Hammer Wet ConeHammer Surf. Hammer Dry Strength,Wet- W - D * ^ psi^ Static^ Strength,^ psi^ Static Vert Horiz^ Vert^ Horiz^ cured^ Cured^ x^ E^10^^ -6^ çuredWet-^ W-DCured^ x^ ®^10 - 15^16 20^23^1920 3 .^ 3^^2220 3.8 7 17^20 22 26 l6l0^ 3 .3 0^^1800 3. 18 20 22 25^1820 2 .6 7^ I75O^ 3. to 20 22 22 26 1680 3 .1 1 I98O^ 3.7 9 (^22) 25 27 29^2220 3.20^ 28to^ 5. l b (^16) 19 23^1710 2.95^^2020 3. I k^18 20 22 1820 3.19^ 23^0^ 3. I k (^18) 19 25^1780 3.02^2660 5. (^16) 19^20 2 b^^2220 3. 20 2 b^ 23 25 223O^ b. 2 9 l b l6 (^) 19^22 li. 18 22 2 b 15^18 21 2 b 17^18 22^25 22 22 22 27 I k l6 21 23 15^18^23 2 b l6 (^18) 23 2 b 17^20^23 21 2 k^ 2 b^^30

A v g l6.8 (^) 19 .3 21 .7 2 b. 9^^1760 1830 2120 229O SDf 2. k (^) 2 .7 1-9 2.1^ 120.5^ 198.8^ 396.8^ 210. CVttl ^ -3 ltoO^ 8.8^ Q. k^ 6.8^ 10.6^ I8.7^ 9.

Test Load lb

Hammer Rdngs Cone Cone Surf. Wet Surf.Dry

Prism Data (Pulse) Velocity (fps x 10 ~ 3 ) (^) StrengthCompr. psi

Flexural^ Beam Strength, psi

Data Sonic x IO"

Hammer 12- x 12-^ Read ings in. face 6- in. x face12-^ Wet- cured W-D Cured 0 20 16.5 15.3 1730 to^5 5.5O^^2 b 25O 21 16.2^ 15 .^ to^5 5OO 20 16.3 15 .^^ too^^18 750 19 1 6. k^ 15.3 350 18 1000 21 16.2^ 15. 0 29 16.2^ 15.3^2570 25O (^) 31 16.7 15.3 52O^ 5.26^26 5OO 32 16.^ 15.3 to5^26 750 31 *** 16.5^ 15.3^^3 to^^25 1000 32 16.5 15. 0 2 b 16.^^ 15.7 2670 250^2 b^ 16.3^ 15.8^ 5to^ 5 .1 1^^22 500 26 1 6. k^ 15.7^370 (^750) 25 16.5^ 15.8^ too^19 (^1000) 25 16.^ k^ 15. 0 32^1 6. b^ 16.O^^3310 (^250) 3 ^ 16.7 16.O^ too^ 5.01^28 500 36 16.8^ 16.I^ too^25 750 35 16.6^ I6.I^^355 1000 3 ^ 17.O^ 16.O^^365 (^0) 27 17.3 16.6^ 237O 250 28 17.3 16. (^500 28) 17.3 1 6. 750 28 17.7 16. 1000 28 17.6^ 16.

*** Each hammer reading reported is the average of the** 10 best suited of 15 readings. ** t Wet-dryStandard cured, deviation. ■ft Coefficient of variation.