Download Mechanical Properties of Metals and more Slides Engineering in PDF only on Docsity!

Chapter 8 - AMSE 205 Spring ‘^

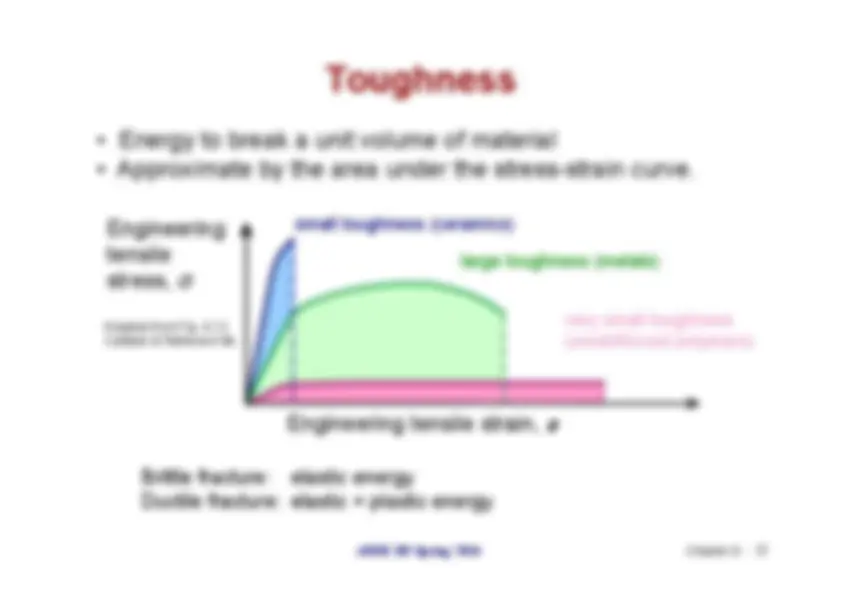

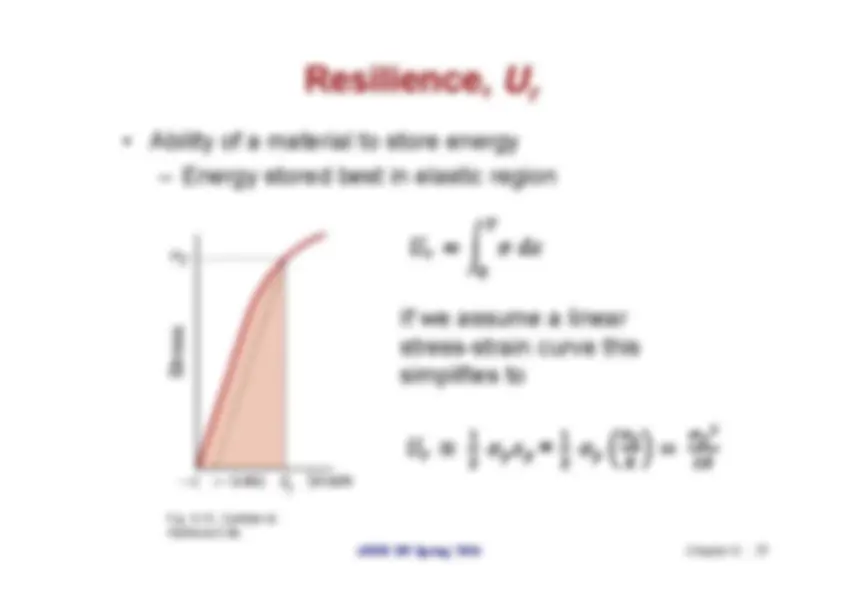

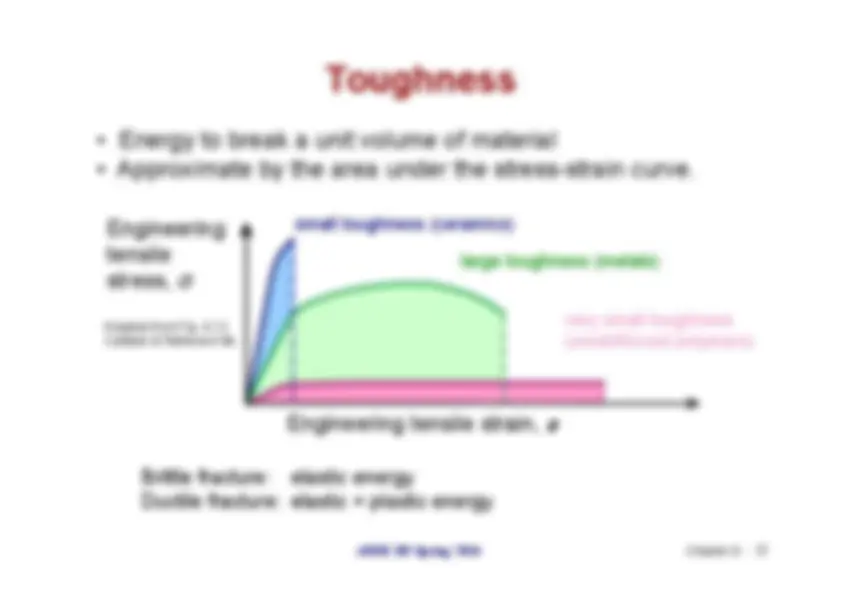

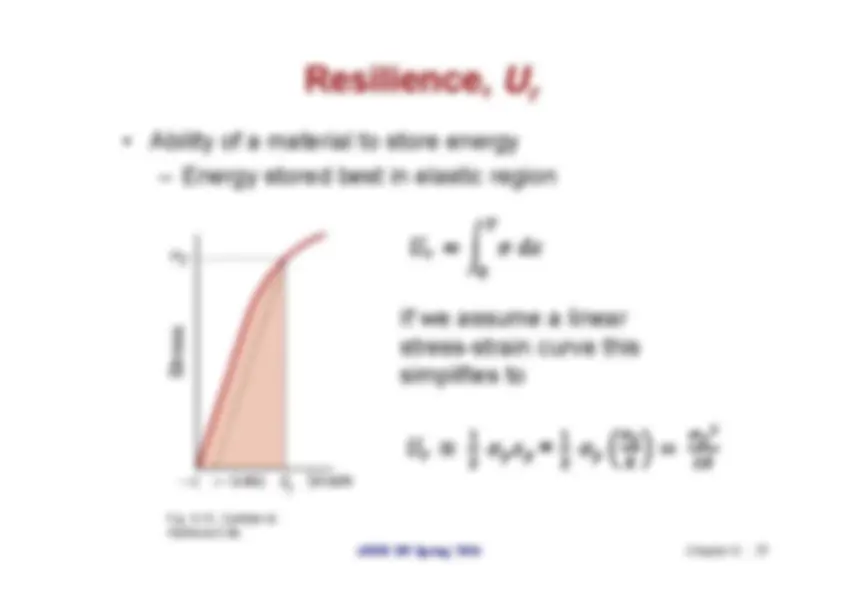

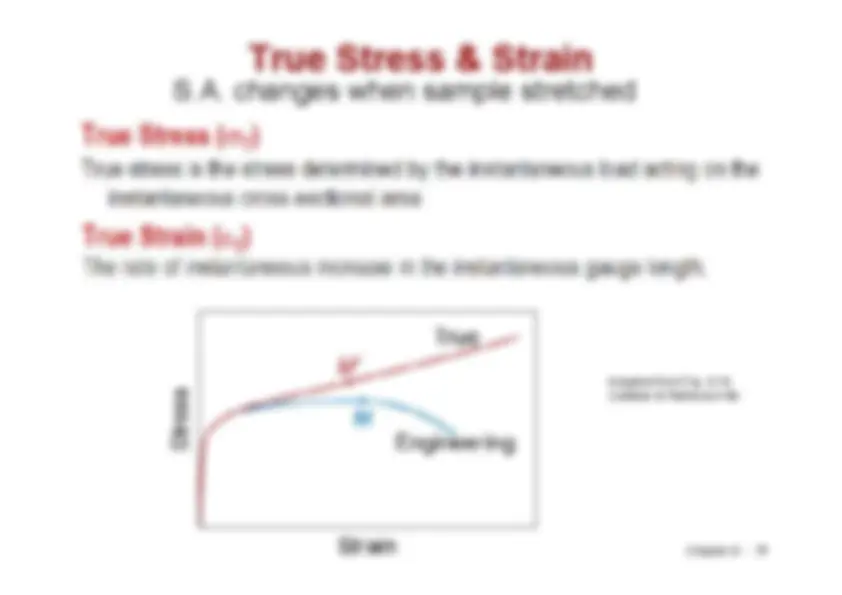

ISSUES TO ADDRESS...• Stress and strain: What are they and why arethey used instead of load and deformation?• Elastic behavior: When loads are small, how muchdeformation occurs? What materials deform least?• Plastic behavior: At what point does permanentdeformation occur? What materials are mostresistant to permanent deformation?• Toughness and ductility: What are they and howdo we measure them?

Chapter 8:

Mechanical Properties of Metals

Chapter 8 - AMSE 205 Spring ‘^

Elastic Deformation Elastic means reversible!

2. Small load^ bondsstretch δ F

1. Initial^

3. Unload return toinitial

F

Linear-elasticNon-Linear-elastic^ δ

Chapter 8 - AMSE 205 Spring ‘^

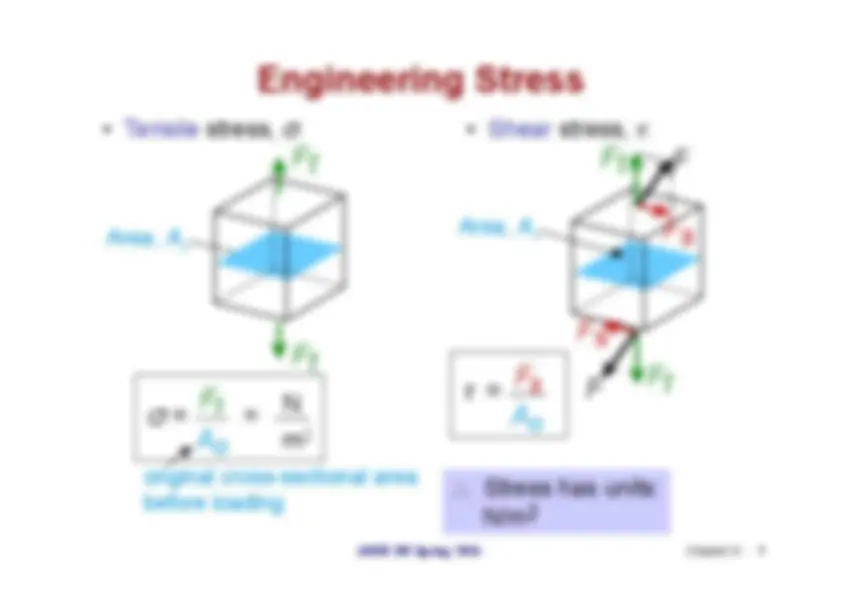

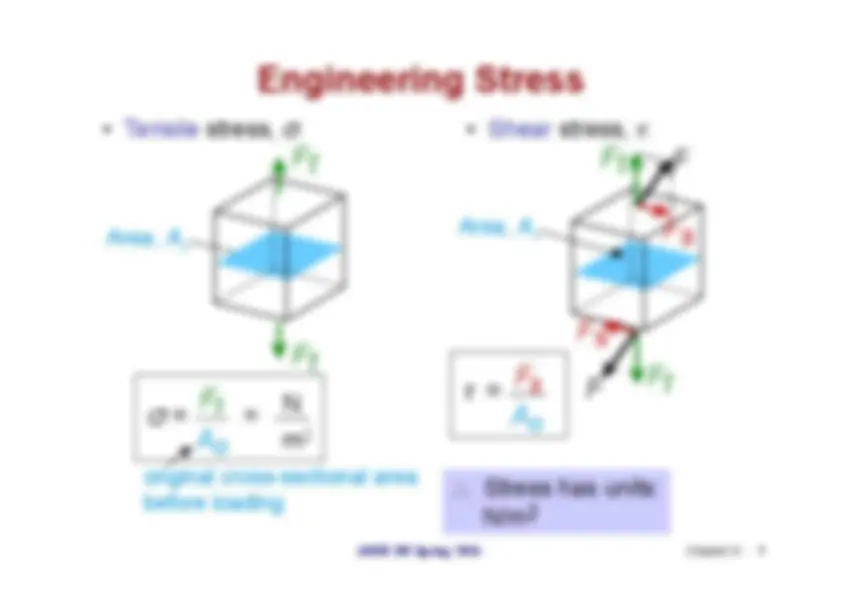

^ Stress has units:^2 N/m

Engineering Stress

• Shear stress,^

Area,^ A^ o

FtF Fs Fs FtF

Fs τ = A^ o

• Tensile stress,

σ : F N t = σ = 2 m A o original cross-sectional areabefore loading

Area,^ A^ o

Ft Ft

Chapter 8 - AMSE 205 Spring ‘^

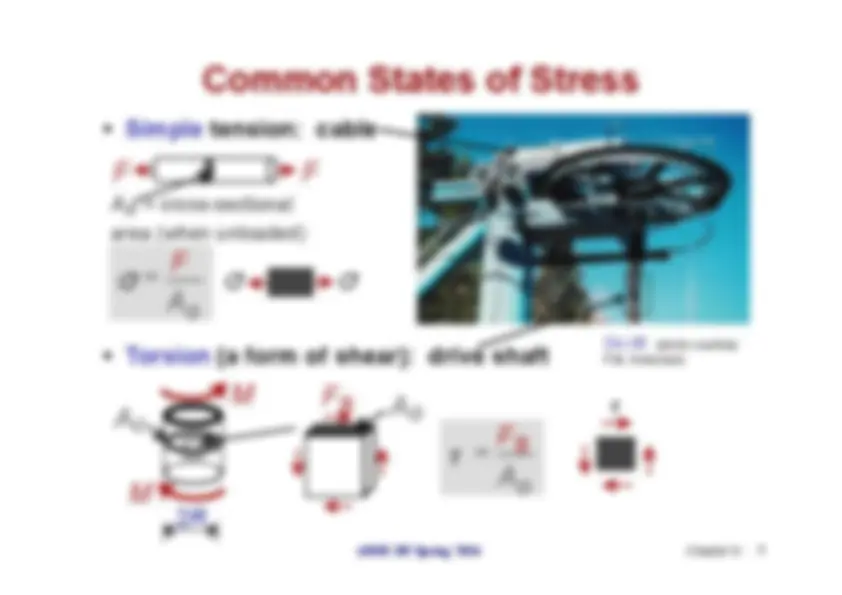

• Simple tension: cable

Common States of Stress F = σ A o

Fs = τ Ao

M^ M

A^ o

• Torsion (a form of shear): drive shaft FsA^ c^2 R

Ski lift^ (photo courtesy P.M. Anderson)

Ao = cross-sectional^ area (when unloaded)

F

F

Chapter 8 - AMSE 205 Spring ‘^

**- Bi-axial tension:

- Hydrostatic compression:**

Pressurized tank

σ^ < 0 h (photo courtesyP.M. Anderson)

(photo courtesyP.M. Anderson)

OTHER COMMON STRESS STATES (ii)

Fish under water

σ > 0 θ^ σ > 0 z^

Chapter 8 - AMSE 205 Spring ‘^

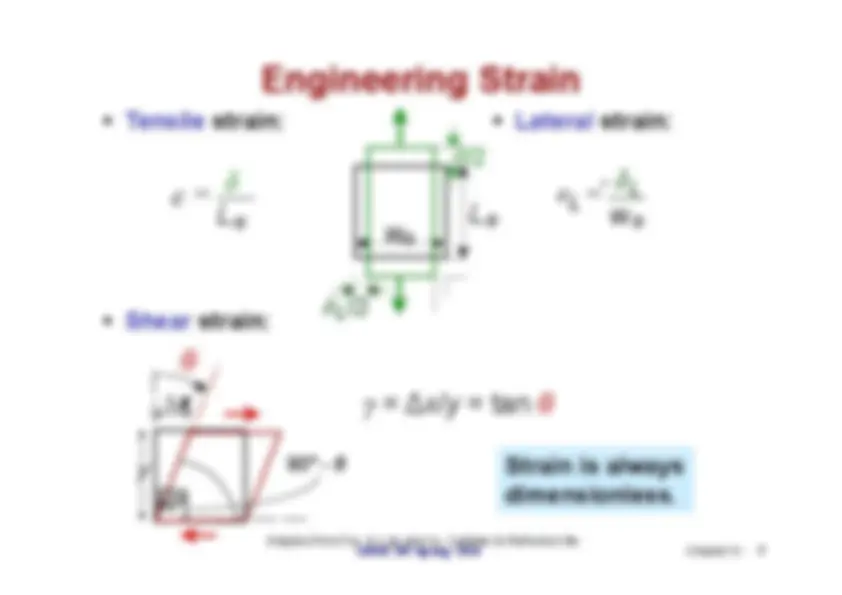

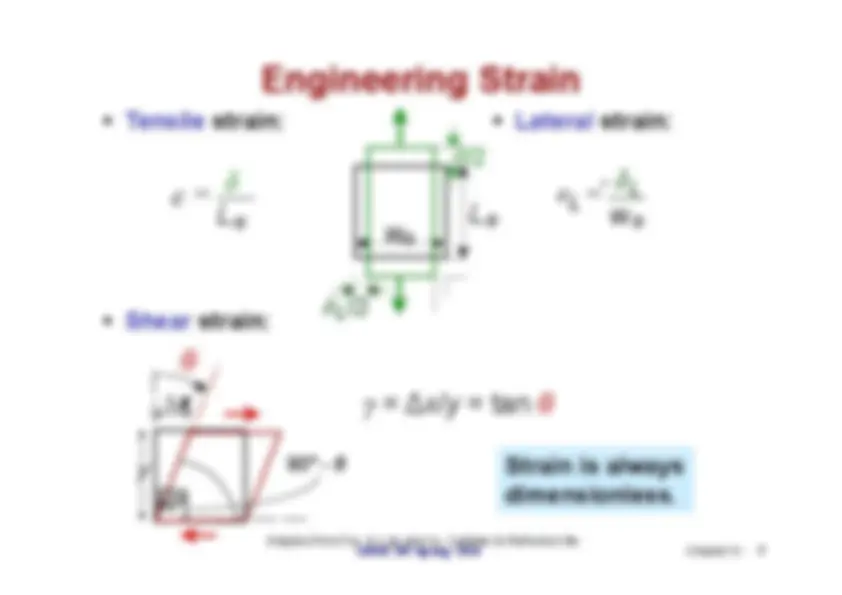

• Tensile strain:

• Lateral strain: Strain is alwaysdimensionless.

Engineering Strain• Shear strain: θ x γ^ = Δ x 90º -^ θy 90º

/ y^ = tan^ θ

δ = L^ o^ Adapted from Fig. 8.1 (a) and (c),

δ /2^ -^ L^ owo Callister & Rethwisch 9e.

δL = L w^ o

δ /2 L

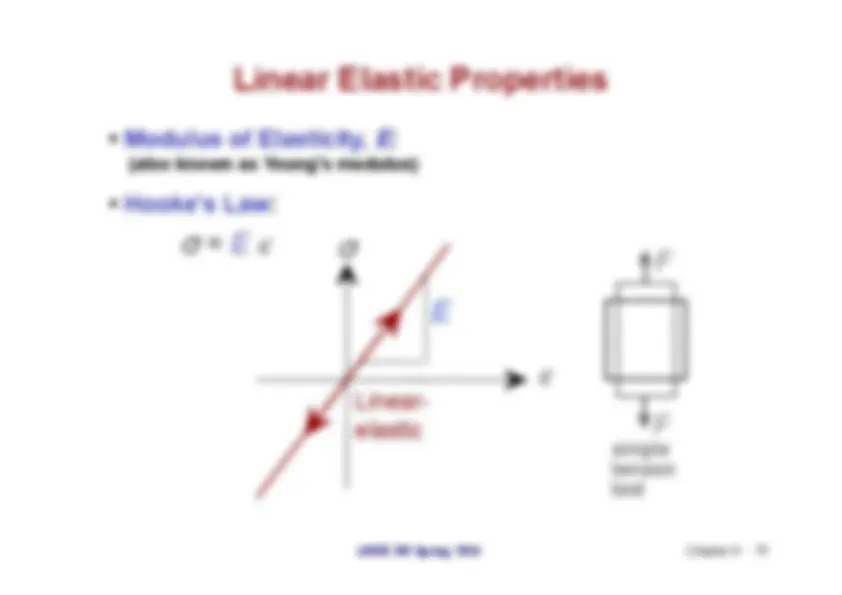

Chapter 8 - AMSE 205 Spring ‘^ Linear Elastic Properties• Modulus of Elasticity,^ E : (also known as Young's modulus)• Hooke's Law: σ = E^ ^ σ^ Linear-elastic

E^

F F simpletensiontest

Chapter 8 - AMSE 205 Spring ‘^ Poisson's ratio,

ν

ν : Ratio between radial and axial strainsUnits:^ E : [GPa] or [psi]^ ν : dimensionless

> 0.50 density increases = 0.50 no volume change < 0.50 density decreases(voids form) L^ - ν L ν = - metals: ν ~ 0.33ceramics: ν ~ 0.25polymers: ν ~ 0.

Chapter 8 - AMSE 205 Spring ‘^

• Elastic Shearmodulus,^ G :

τ^ G^ γ

Other Elastic Properties τ = G^ γ

M^ simpletorsiontest M

• Special relations for isotropic materials:^ E = G^^ 2(1 +^ ν )

Chapter 8 - AMSE 205 Spring ‘^

GraphiteMetalsCeramicsPolymers AlloysSemicond

Composites/fibers

E (GPa)

Based on data in Table B.2, Callister & Rethwisch 9e. Composite data based onreinforced epoxy with 60 vol%of alignedcarbon (CFRE),aramid (AFRE), orglass (GFRE)fibers.

Young ’ s Moduli: Comparison Al oxideMolybdenumSi nitrideSteel, NiTantalumSi crystalPlatinumZinc, TiSilver, GoldGlass -sodaAluminumMagnesium,Concrete 9 10 PaGraphite^81 0.6 0.

Carbon fibers onlyAramid fibers onlyGlass fibers onlyGFRECFRE AFRE(^ fibers) *Epoxy onlyPC Wood(^ grain) 12001000 Diamond^800600 Si carbide^400 Tungsten^200 <111><100>Cu alloys^1008060 Tin^402010642 0.8 0.

CFRE(|| fibers)AFRE(|| fibers)GFRE(|| fibers)GFRE(^ fibers)CFRE(^ fibers) *PolyesterPETPS PPHDPEPTFE LDPE

Chapter 8 - AMSE 205 Spring ‘^

• Stress at which

noticeable^ plastic deformation hasoccurred. when

= 0.002 p^

Yield Strength,

σ y = yield strength y Note: for 2 inch sample^ = 0.002 =^

z / z z = 0.004 in

σ tensile stress, σy e engineering strain,^ = 0.002Adapted from Fig. 8.10 (a), p Callister & Rethwisch 9e.

Chapter 8 - AMSE 205 Spring ‘^

Typical stress-strain behavior for a metal

Typical stress-strain behavior for steels

Chapter 8 - AMSE 205 Spring ‘^

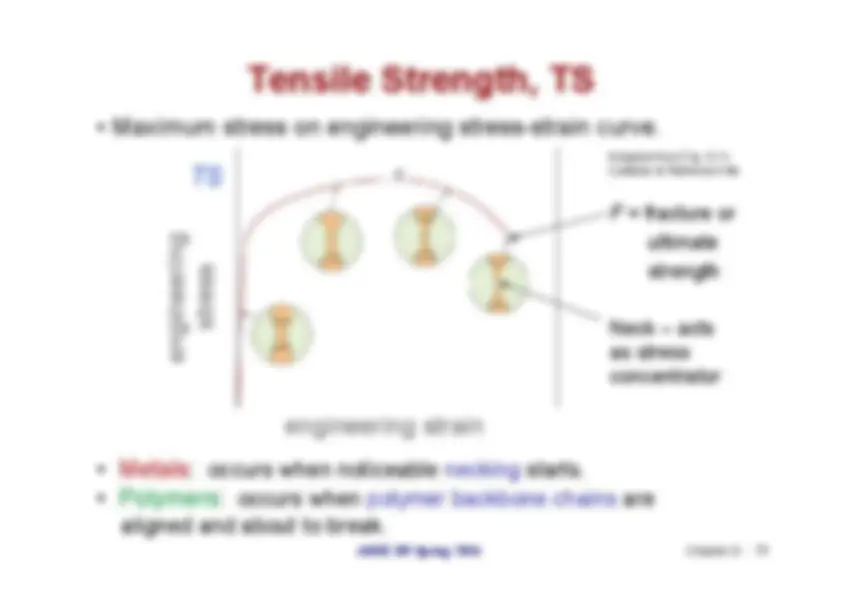

Tensile Strength, TS • Metals: occurs when noticeable necking starts.• Polymers: occurs when polymer backbone chains arealigned and about to break.

Adapted from Fig. 8.11, Callister & Rethwisch 9e.

y

Typical response of a metal^ strain

F^ = fracture orultimatestrengthNeck – actsas stressconcentrator

• Maximum stress on engineering stress-strain curve.^ TS stress^ engineeringengineering strain

Chapter 8 - AMSE 205 Spring ‘^

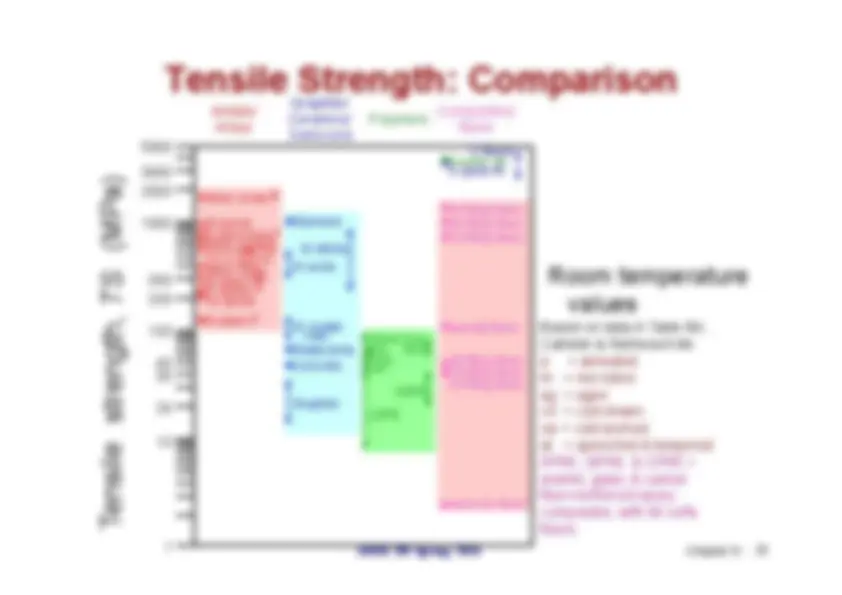

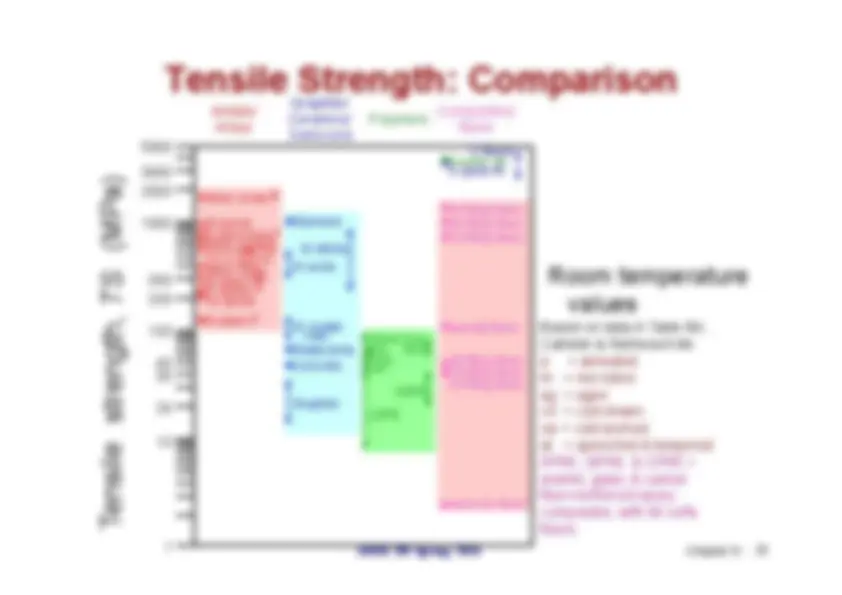

Tensile Strength: Comparison Graphite/Metals/Ceramics/AlloysSemicond^ Si crystal<100>

Composites/Polymersfibers

(MPa)^ TS^ strength, Tensile

Nylon 6,6PVC

qtSteel (4140) W (pure) 1000 aTi (5Al-2.5Sn) aSteel (4140) cwCu (71500) hrCu (71500) Steel (1020)ag 300 Al (6061) Ti (pure) a 200 Ta (pure)aAl (6061) 10010

PETPC PP LDPE

500030002000 DiamondSi nitrideAl oxide Glass-soda^40 Concrete^30 Graphite^20

wood(|| fiber)HDPE wood (^ fiber)

C fibersAramid^ fibE-glass fibAFRE(|| fiber)GFRE(|| fiber)CFRE(|| fiber)Room temperaturevaluesBased on data in Table B4,^ Callister & Rethwisch 9e. GFRE(^ fiber)^ a^ = annealedCFRE(^ fiber)hr^ = hot rolledAFRE(^ fiber)ag = agedcd = cold drawncw = cold workedqt^ = quenched & temperedAFRE, GFRE, & CFRE =aramid, glass, & carbonfiber-reinforced epoxycomposites, with 60 vol%fibers.