Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

The ISO System of Limits and Fits is a coordinated system of hole and shaft tolerances for engineering and manufacturing used for cutting tools, ...

Typology: Study notes

1 / 39

This page cannot be seen from the preview

Don't miss anything!

Hole Shaft Basis Basis

H11/c11 C11/h11 Loose running fit for wide commercial tolerances or allowances on external members. More H9/d9 D9/h9 Free running fit not for use where accuracy is essential, but good for large Clearance Clearance temperature variations, high running speeds, or heavy journal pressures. H8/f7 F8/h7 Close running fit for running on accurate machines and for accurate Fits location at moderate speeds and journal pressures. H7/g6 G7/h6 Sliding fit not intended to run freely, but to move and turn freely and locate accurately. H7/h6 H7/h6 Locational clearance fit provides snug fit for locating stationary parts; but can be freely assembled and disassembled. Transition H7/k6 K7/h6 Locational transition fit for accurate location, a compromise between clearance and interference. Fits H7/n6 N7/h6 Locational transition fit for more accurate location where greater interference is permissible. H7/p6 1 P7/h6 Locational interference fit for parts requiring rigidity and alignment with prime accuracy of location but without special bore pressure requirements. Interference H7/s6 S7/h6 Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. More Fits H7/u6 U7/h6 Force fit suitable for parts which can be highly stressed or for shrink fits Interference where the heavy pressing forces required are impractical. (^1) Transition fit for basic sizes in range from 0 through 3 mm.

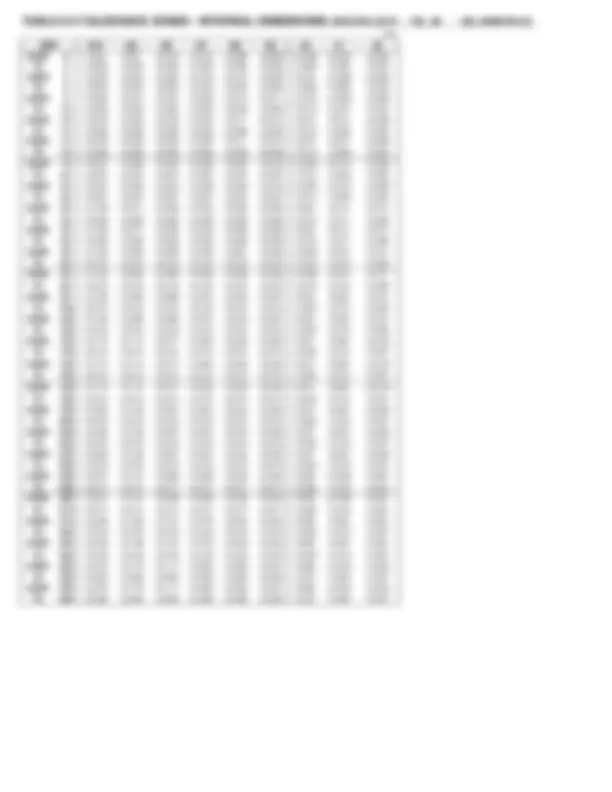

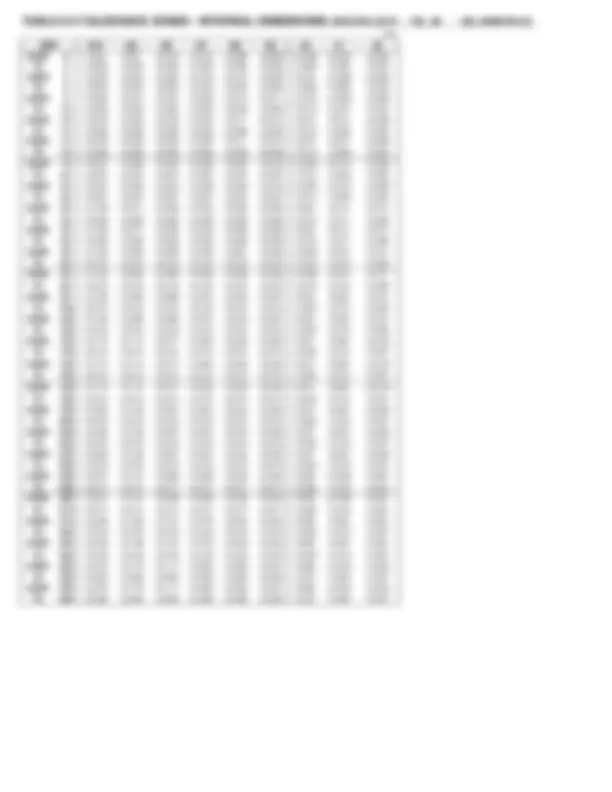

mm LOOSE FREE CLOSE SLIDING LOCATIONAL RUNNING RUNNING RUNNING CLEARANCE

NOTES: 1. Select nominal sizes to preference rating as follows: F = First Choice, S = Second Choice, T = Third Choice.

TABLE 6-4 PREFERRED SHAFT BASIS CLEARANCE FITS (ANSI B4.2) mm BASIC LOOSE RUNNING FREE RUNNING CLOSE RUNNING SLIDING LOC CLEARANCE

NOTES: 1. Select nominal sizes to preference rating as follows: F = First Choice, S = Second Choice, T = Third Choice.

TABLE 6-5 PREFERRED SHAFT BASIS TRANSITION AND INTERFERENCE FITS (ANSI B4.2) mm BASIC LOCATIONAL TRANSN LOCATIONAL TRANSN LOCATIONAL INTERF MEDIUM DRIVE FORCE

NOTES: 1. Select nominal sizes to preference rating as follows: F = First Choice, S = Second Choice, T = Third Choice.

TABLE 6-9 TOLERANCE ZONES - INTERNAL DIMENSIONS (HOLES) (G10 ... G5, J8... J6) (ANSI B4.2)

TABLE 6-18 TOLERANCE ZONES - EXTERNAL DIMENSIONS (SHAFTS) (a14 ... a9, b14 ... b9) (ANSI B4.2)

- SIZE H11 c BASIC HOLE SHAFT HOLE SHAFT HOLE SHAFT HOLE SHAFT HOLE SHAFT - H9 d DIFF - H8 f DIFF - H7 g DIFF - H7 h DIFF