Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

A study by christoper neff on the simplification of a two-stroke internal combustion engine model. The study uses euler's method for ordinary differential equations to replicate the results provided by kranc in the ijmee journal. The engine is operated on an otto cycle using air as the working fluid, and the model takes into account the torque inhibiting movement caused by weight and the torque from a pressure force. The study provides equations, nomenclature, and references for further study.

Typology: Study notes

1 / 14

This page cannot be seen from the preview

Don't miss anything!

Volume 5 | 2012 Fall Article 5

2013

Christofer Neff University of South Florida Advisors: Arcadii Grinshpan, Mathematics and Statistics Scott Campbell, Chemical & Biomedical Engineering Problem Suggested By: Scott Campbell

Follow this and additional works at: https://digitalcommons.usf.edu/ujmm Part of the Heat Transfer, Combustion Commons, and the Mathematics Commons

UJMM is an open access journal, free to authors and readers, and relies on your support: Donate Now

Recommended CitationRecommended Citation Neff, Christofer (2013) "A Simplified Model of the Internal Combustion Engine," Mathematical Modeling: One + Two: Vol. 5: Iss. 1, Article 5. Undergraduate Journal of DOI: http://dx.doi.org/10.5038/2326-3652.5.1. Available at: https://digitalcommons.usf.edu/ujmm/vol5/iss1/

AbstractAbstract This project further investigates a model of a simplified internal combustion engine considered by Kranc in 1977. Using Euler’s method for ordinary differential equations, we modeled the interaction between the engine’s flywheel and thermodynamic power cycle. Approximating with sufficiently small time intervals (0.001 seconds over a period of 12 seconds) reproduced Kranc’s results with the engine having an average angular velocity of 72/sec.

KeywordsKeywords internal combustion engine, thermodynamics, angular velocity

This article is available in Undergraduate Journal of Mathematical Modeling: One + Two: https://digitalcommons.usf.edu/ujmm/vol5/iss1/

A SIMPLIFIED M ODEL OF THE INTERNAL COMBUSTION ENGINE 3

Machines have purpose, and that purpose is to serve as a tool to achieve a specific goal or end. Modeling systems of machines is essential to most fields of engineering and research ranging from medicine, media, mechatronics, databases, and even tools we use constantly such as the internet. Mathematical analysis allows engineers and scientist to intelligently predict the performance of a machine based on its approximate specifications. The objective of this project is to recreate the given model of a simplified internal combustion engine to a suitably small approximation using Euler’s method for ordinary differential equations.

Before discussing the mathematics of the problem it is important to understand the concepts behind the movement of a two-stroke internal combustion engine. The two factors which most affect the movement of the two-stroke internal combustion engine are: 1) the working fluid and the dimensions relative to the piston or flywheel and 2) the relationship between the engine’s temperature, pressure, and volume. Friction and the weight of parts, such as the connecting rod of the piston, are also relevant to the model, however these factors will be negated due to the use of air as the working fluid and the assumption that the connecting rod is massless or light enough to be ignored. In this case, conceptualizing the system is vital and best represented by Figure 1 as a reference. Beginning with the movement of the engine, two primary and related movements are modeled by the fundamental equations of this project. The first being the movement of the scotch yoke linkage which converts translational or straight motion into rotational motion. Looking at

Undergraduate Journal of Mathematical Modeling: One + Two, Vol. 5, Iss. 1 [2012], Art. 5

https://digitalcommons.usf.edu/ujmm/vol5/iss1/5DOI: http://dx.doi.org/10.5038/2326-3652.5.1.

4 CHRISTOFER NEFF Figure 1, this piece is shaped as a hollow rectangle attached to a pin and allows a straighter more direct flow of power from the flywheel which is the circular portion. Without the scotch yoke linkage power would not be delivered as cleanly causing greater variations and less efficient data. Variables relative to this movement are radius of the flywheel denoted by 𝑅 = 0.305 m and the crank angle 𝜃. For this model, the crank angle is taken in radians, varying from 0 < 𝜃 < 2𝜋. Since the stroke position directly corresponds to the position of the flywheel, the crank angle determines whether the engine is on a compression stroke or a combustion stroke. The beauty of the two- stroke engine is that in one revolution a full power cycle is taken whereas a four-stroke engine takes 2 revolutions to complete a full power cycle. For this engine, a break between the compression stroke and the combustion stroke is what will cause the final graph to fluctuate in a wave-like pattern. The final graph introduced in Kranc’s journal entry is as follows:

Figure 2 : Simplified Engines cycle power output of 72 rad/sec [Extracted from (Kranc 1977)]

Neff: A Simplified Model of the Internal Combustion Engine

Produced by The Berkeley Electronic Press, 2012

6 CHRISTOFER NEFF this system comes to light. In particular, the fundamental equation is derived by summing the moments of inertia on the flywheel assuming the connecting rod is massless (Kranc 1977). At this point we model the torque inhibiting movement caused by the weight present as well as the torque from a pressure force 𝐼 𝜃̈ = 𝑇𝑝𝑖𝑠𝑡𝑜𝑛 − 𝑇𝑙𝑜𝑎𝑑 (2) where 𝐼 = 3.171 kg m^2 is the moment of inertia, 𝜃̈ is angular acceleration or second derivative of 𝜃, 𝑇𝑝𝑖𝑠𝑡𝑜𝑛 is the torque of the piston, and 𝑇𝑝𝑖𝑠𝑡𝑜𝑛 is the torque of the load accomplished by a Scotch yoke linkage which converts translational motion into rotational motion. In the ideal case, the motion of the piston would be purely sinusoidal with a uniform angular velocity, but this is not the case in most real world applications. To simulate real world application, a massless connecting rod and scotch yoke linkage are used as fluctuations are prominent when the flywheels mass is sufficiently small. A constant pressure force acts on the pistons area of 𝐴 = 0.001883 𝑚 2 , and acts as a moment arm of 𝑅 sin 𝜃 where 𝑅 = 0.305 m is the radius of the flywheel and 𝜃 is the crank angle. The constant force will affect the torque of the piston or rather take its place, however the torque of the load is affected by the angular velocity of the piston along with a load constant 𝐶 = 0.0113𝑘𝑔𝑚 2. Additionally, the torque of the load is modified as it is proportional to the square of the angular velocity changing (1) to, 𝐼𝜃̈ = 𝑃 𝐴 (𝑅 sin 𝜃) − 𝐶𝜔^2 (3) Modifying (2) further in order to calculate the pressure 𝑃, it is assumed that the engine is operating on an Otto cycle using air as the working fluid. Ideal gas law variables of pressure, volume and temperature are to be kept constant during the power cycle. Exceptions only apply to

Neff: A Simplified Model of the Internal Combustion Engine

Produced by The Berkeley Electronic Press, 2012

A SIMPLIFIED M ODEL OF THE INTERNAL COMBUSTION ENGINE 7 the dependent and independent variables along with any changes in throttle; modification in speed ignored. Cylinder pressure during compression is then given with a polytropic index of 𝑛 = 1.3 as an exponent to account for temperature with pressure at this cycle being 𝑃 1 = 0.1𝑀𝑃𝑎. At expansion the polytropic index is also used, yet the pressure will be for that of expansion is 𝑃 3 = 10.3𝑀𝑃𝑎. The volume of the cylinder at any stroke is represented by the relationship of, 𝑉 = (𝑅 − 𝑅 cos 𝜃 + 𝑥𝑜)^ 𝐴 (4) with 𝑥𝑜 = 0.0254 𝑚 being the clearance distance, and the moment arm of volume is evaluated at two points for each stroke. With this in mind a ratio is given for volume at each stroke being the beginning crank angle over the current crank angle at some specific point denoted by time. Then, the fundamental equation comes to light by uniting (2) and (3) and transferring the moment of inertia on the flywheel to the right:

⎪^ ⎧𝑃^3 �𝑅 𝑅^ −−^ 𝑅𝑅^ coscos^ 𝜃 𝜃^1 ++ 𝑥𝑥𝑜𝑜�

𝑛 (^) 𝐴 𝑅 sin 𝜃 𝐼 −

𝑃 1 �𝑅 − 𝑅𝑅 − 𝑅^ cos cos^ 𝜃 𝜃^3 ++ 𝑥𝑥𝑜𝑜�

𝑛 (^) 𝐴 𝑅 sin 𝜃 𝐼 −

In order to complete the model, we take the values for 𝜃 1 < 𝜃 < 𝜃 2 and input 𝜋 < 𝜃 < 2 𝜋 and for 𝜃 3 < 𝜃 < 𝜃 4 respectively becomes 0 < 𝜃 < 𝜋. The reason 𝜃 1 begins at a value greater than zero is that the Otto cycle in this case begins at the intake stroke or combustion stroke meaning the flywheel is at π. Now that we have all of our variables to the right side of the equation and angular acceleration on the left side, what is left to do is simplify for angular velocity from angular acceleration.

Undergraduate Journal of Mathematical Modeling: One + Two, Vol. 5, Iss. 1 [2012], Art. 5

https://digitalcommons.usf.edu/ujmm/vol5/iss1/5DOI: http://dx.doi.org/10.5038/2326-3652.5.1.

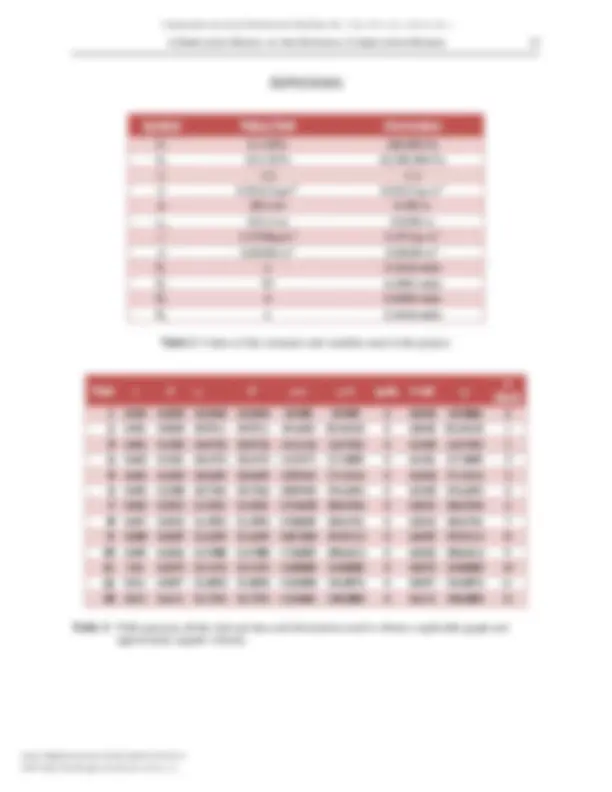

A SIMPLIFIED M ODEL OF THE INTERNAL COMBUSTION ENGINE 9 𝜔𝑛𝑒𝑤 = 𝜔𝑝𝑟𝑒𝑣𝑖𝑜𝑢𝑠 + ∆𝑡 𝜔𝑝𝑟𝑒𝑣𝑖𝑜𝑢𝑠^ ′^ (8) and, 𝜃𝑛𝑒𝑤 = 𝜃𝑝𝑟𝑒𝑣𝑖𝑜𝑢𝑠 + ∆𝑡 𝜃𝑝𝑟𝑒𝑣𝑖𝑜𝑢𝑠^ ′^ (9) Equations (5), (6), (7), and (8) can be tabulated to solve for the unknowns and see how the rate of change relates these variables (refer to Table 3 given in Appendix for numerical results). Essentially, the smaller the time intervals used to test the differential equation, the better the result. Therefore ∆𝑡 = 0.001 𝑠 time intervals were used.

Trial t θ 𝝎 θ' 𝝎 'a 𝝎 'b 1^0 0 50 Eq.(6)^ Eq. (5)a^ Eq. (5)b 2 0.001 Eq.(8) Eq. (7) 49.991 49.440 82.54 2 3 0.002 0. 100 50.07 4 50.07 4 101.214 163. 4 0.003^ 0.150^ 50.237^ 50.237^ 141.94^8 227.58^1 Table 1 : First four iterations of Euler’s method used to approximate (6) An Excel spreadsheet was used to carry out calculation up to 12 seconds. Microsoft Excel graph was then generated to replicate Kranc’s results (see Figures 3 and 4 below).

Figure 3 : Primary chart used to graph angularvelocity against time of some 12, cells.

Figure 4 : A closer look at Figure 3 shows asinusoidal wave.

0

10

20

30

40

50

60

70

80

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Speed (RAD/SEC)

Time (seconds) Angular velocity over time

48

50

52

54

56

58

60

0 0.1 0.2 0.3 0.4 0.

Speed (RAD/SEC)

Time (seconds) Angular velocity over time

Undergraduate Journal of Mathematical Modeling: One + Two, Vol. 5, Iss. 1 [2012], Art. 5

https://digitalcommons.usf.edu/ujmm/vol5/iss1/5DOI: http://dx.doi.org/10.5038/2326-3652.5.1.

10 CHRISTOFER NEFF

Applying Euler’s modified method for estimating differential equations to the governing equations yields an average angular velocity over time of 72 𝑠 −1^ as well as a spot on image of Kranc’s graph (Figure 2). The results were replicable, meaning that under the circumstances the information provided is accurate and if the same mathematical methodology is applied someone would reach the same end of a convergence of 72 𝑠 −1^ for this theoretical application of an internal combustion engine. Hence, a similar if not equal model of a simplified internal combustion engine was achieved.

The objective of this project was met by recreating a manageable model of a simplified internal combustion engine to a suitably small approximation using Euler’s method for ordinary differential equations. The graph in Figure 3 was able to emulate a close match to the reputable source of data by using sufficiently small intervals. For future reference, this project could be expanded by modifying the system to recreate a four-stroke engine or reciprocating compressor. The efficiency of the engine could also be measured to test what kind of output a simplified model internal combustion engine has under these specific conditions, constants, and variables. Parameters of the project could be changed to show what kind of effect each has on the graph of angular velocity over time, taking note of which variables can vary without affecting the balance of the engine greatly. In a usual case, the steady state equation for a fluid that has a constant flow could have been applied in this project as well. In the end, the machine, the engine in this case, proved to be reliable under some set of conditions which is ideal in our ongoing pursuit of progress.

Neff: A Simplified Model of the Internal Combustion Engine

Produced by The Berkeley Electronic Press, 2012

12 CHRISTOFER NEFF

Serway, Raymond A., and John W. Jewett. Physics for Scientists and Engineers. 8th ed. Vol. 1. Belmont, CA: Brooks/Cole CENGAGE Learning, 2010. Stewart, James. Essential Calculus: Early Transcendentals. Belmont, CA: Brooks/Cole, 2011. Kranc, SC. "A Simplified Model of the Internal Combustion Engine." International Journal of Mechanical Engineering Education (IJMEE) - IMechE & UMIST 5.4 (1977): 343-46. Campbell, Scott W. "Project Development." Personal interview. 20 Feb. 2012. 3 May 2012. Campbell, Scott. Euler's Method. Tampa: University of South Florida, 2012. PDF. Siyambalapitiya, Chamila. "Project Development." Personal interview. 27 Apr. 2012. Adkins, William A., and Mark G. Davidson. Ordinary Differential Equations. Berlin: Springer,

"Compression and Expansion of Gases." Compression and Expansion of Gases. Engineeringtoolbox.com, n.d. Web. 01 Apr. 2013. http://www.engineeringtoolbox.com/

Neff: A Simplified Model of the Internal Combustion Engine

Produced by The Berkeley Electronic Press, 2012

A SIMPLIFIED M ODEL OF THE INTERNAL COMBUSTION ENGINE 13

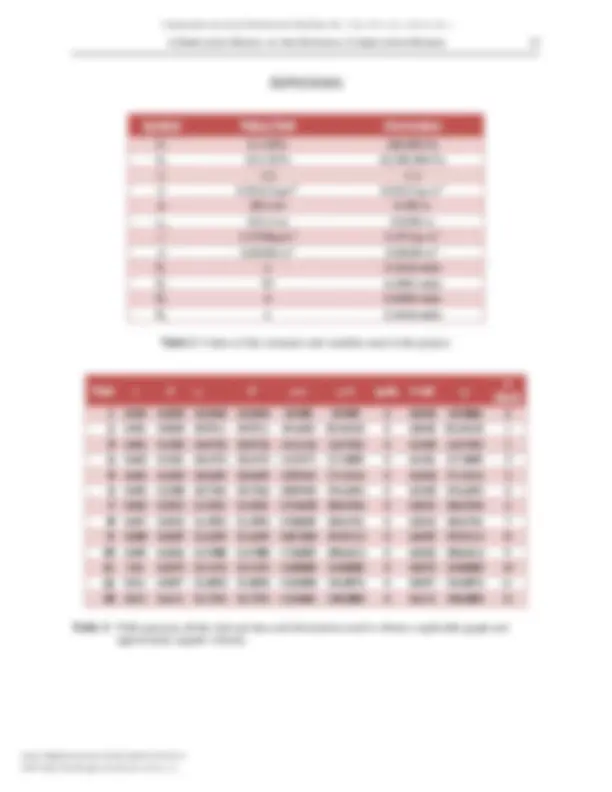

Symbol Value/Unit Conversion 𝑃 1 0.1 𝑀𝑃𝑎 100 , 000 𝑃𝑎 𝑃 3 10.3^ 𝑀𝑃𝑎^10 ,^300 ,^000 𝑃𝑎 𝑛 1.3 1. 𝐶 0.0113 𝑘𝑔𝑚^2 0.0113 𝑘𝑔 𝑚^2 𝑅 305 𝑚𝑚^ 0.305^ 𝑚 𝑥𝑜 25.4 𝑚𝑚 0.0254 𝑚 𝐼 3.171^0 𝑘𝑔𝑚^2 3.171^ 𝑘𝑔^ 𝑚^2 𝐴 0.00188 𝑚^2 0.00188 𝑚^2 𝜃 1 𝜋 3. 1416 rads 𝜃 2 2 𝜋^6. 2832 rads 𝜃 3 0 0. 0000 rads 𝜃 4 𝜋 3. 1416 rads Table 2 : Values of the constants and variables used in the project.

Trial 𝒕 𝜽 𝝎 𝜽′ 𝛚′𝒂 𝛚′𝒃 cycle 𝜽 ref. 𝛚′ (^) (Rad)𝜽 1 0 .000 0 .0000 50 .0000 50 .0000 - 8.908 9 - 8.908 9 0 0 .0000 - 8.90886 0 2 0.001 0.05 00 49.991 1 49.991 1 49.440 3 82.54155 0 0.05 00 82.54155 1 3 0.002 0.1000 50.0736 50.0736 101.214 4 163.7052 0 0. 1000 163.7052 2 4 0.003 0.1501 50.2373 50.2373 141.9477 227.5809 0 0.150 1 227.5809 3 5 0.004 0.2003 50.4649 50.4649 169.9542 271.5226 0 0.2003 271.5226 4 6 0.005 0.2508 50.7364 50.7364 185.9504 296.6494 0 0.250 8 296.6494 5 7 0.006 0.3015 51.0331 51.033 1 192.0628 306.2906 0 0.3015 306.2906 6 8 0.007 0.3525 51.3394 51.339 4 190.860 9 304.4701 0 0.3525 304.4701 7 9 0.008 0.403 9 51.6439 51.643 9 184.7280 294.9213 0 0.403 9 294.9213 8 10 0.009 0.455 6 51.9388 51.938 8 175.5839 280.6513 0 0.4555 280.6513 9 11 0.01 0.507 5 52.2194 52.2194 164.8383 263.8685 0 0.507 5 263.8685 10 12 0.011 0.559 7 52.4833 52.483 3 153.45 80 246.0876 0 0.559 7 246.0876 11 13 0.012 0.612 1 52.7294 52.729 4 142.0681 228.2883 0 0.612 2 228.2883 12 Table 3: Table presents all the relevant data and information used to obtain a replicable graph andapproximate angular velocity.

Undergraduate Journal of Mathematical Modeling: One + Two, Vol. 5, Iss. 1 [2012], Art. 5

https://digitalcommons.usf.edu/ujmm/vol5/iss1/5DOI: http://dx.doi.org/10.5038/2326-3652.5.1.