Study with the several resources on Docsity

Earn points by helping other students or get them with a premium plan

Prepare for your exams

Study with the several resources on Docsity

Earn points to download

Earn points by helping other students or get them with a premium plan

Community

Ask the community for help and clear up your study doubts

Discover the best universities in your country according to Docsity users

Free resources

Download our free guides on studying techniques, anxiety management strategies, and thesis advice from Docsity tutors

Focuses on details and specification of 210 MW thermal power plant boiler. For mechanical and pgdc in power branch

Typology: Thesis

1 / 41

This page cannot be seen from the preview

Don't miss anything!

Description of stage-1 boiler : It is a tangentially fired, balanced draught, natural circulation, radiant reheat type, dry bottom with pulverized coal direct fired boiler. Tangentially fired: It means the flame is touching the fire ball tangentially, this being a corner fired boiler. Balanced draught: Furnace draught is always kept balanced at -10 mm of water column by suitably loading the ID fans under different loading conditions. Natural circulation: Flow of water in the boiler and also flow of steam in the water wall tubes and other water wall circuits to the drum is under natural circulation. No pump is used for circulation of water between drum and water walls. Radiant: Furnace heat is absorbed by radiation only. Flame will not touch the water walls. Also roof super heater, platen water walls and platen superheater absorb heat by radiation and convection. Reheat: The boiler is provided with a reheater where the steam in the cold reheat line is sent to the reheater in the boiler and then to the IP turbine after superheating in the reheater. Dry Bottom : The furnace bottom ash is in solid form only but not in molten state; hence it is called a dry bottom boiler. Direct fired pulverized coal: After initial ignition either with HSD or Heavy oil the pulverized coal is fired on its self ignition and the flame is self sustaining, hence it is called a direct fired boiler.

Boiler is any closed vessel exceeding 22.75 liters in capacity used for steam generation under pressure. First boiler was developed in 1725 and its working pressure was 6 to 10 kg/cm2 and was called Wagon Boiler There are mainly two types of Boilers

Boiler is any closed vessel exceeding 22.75 liters in capacity used for steam generation under pressure. First boiler was developed in 1725 and its working pressure was 6 to 10 kg/cm2 and was called Wagon Boiler There are mainly two types of Boilers

Boiler design Considerations:-

1.0 Boiler structural: The boiler structural is divided into two parts. · Supporting Structure · Galleries and stair ways

1.1 Supporting Structures: Boilers supporting structure consists of a systematic arrangement of columns stiffened with horizontal beams and vertical diagonal bracings and comprise of low carbon steel material. It is composed of 18 main columns and 12 auxiliary columns. The main columns support the main boiler components viz. drum, water wall membrane, panels, superheaters, reheaters, economisers, air preheater, burners and galleries at various levels.

Boiler design Considerations:-

1.0 Boiler structural: The boiler structural is divided into two parts. · Supporting Structure · Galleries and stair ways

1.1 Supporting Structures: Boilers supporting structure consists of a systematic arrangement of columns stiffened with horizontal beams and vertical diagonal bracings and comprise of low carbon steel material. It is composed of 18 main columns and 12 auxiliary columns. The main columns support the main boiler components viz. drum, water wall membrane, panels, superheaters, reheaters, economisers, air preheater, burners and galleries at various levels.

Galleries and stairways: Galleries and stairways around the combustion and heat recovery areas are provided for proper approach to the boiler. Stairways on both the side of Boiler are provided. All the floors are covered with floor gratings of required depth for walkway and are welded to the structure. The total weight of Galleries and stairway are 900 M.T.

Galleries and stairways: Galleries and stairways around the combustion and heat recovery areas are provided for proper approach to the boiler. Stairways on both the side of Boiler are provided. All the floors are covered with floor gratings of required depth for walkway and are welded to the structure. The total weight of Galleries and stairway are 900 M.T.

The auxiliary columns, supports the boiler platforms and other ducts coming in that region. The total weight of supporting structures is about 970 M.T.

The auxiliary columns, supports the boiler platforms and other ducts coming in that region. The total weight of supporting structures is about 970 M.T.

Furnaces may be classified according to the construction of

four wall.

The furnace must provide the following

(^) Accessibility to the boiler for the maintenance and repair work that must be handled from inside the furnace chamber.

Furnaces may be classified according to the construction of

four wall.

The furnace must provide the following

(^) Accessibility to the boiler for the maintenance and repair work that must be handled from inside the furnace chamber.

Following selection factors are taken into consideration:- (^) Lowest capital cost, easy in construction, simplicity safety,

good working condition, easy in maintenance. (^) Availability of auxiliaries (^) Efficient operation, effective for heat transfer well insulate

casings, ability to deliver pure steam with effective drum internals, to generate steam of full capacity.

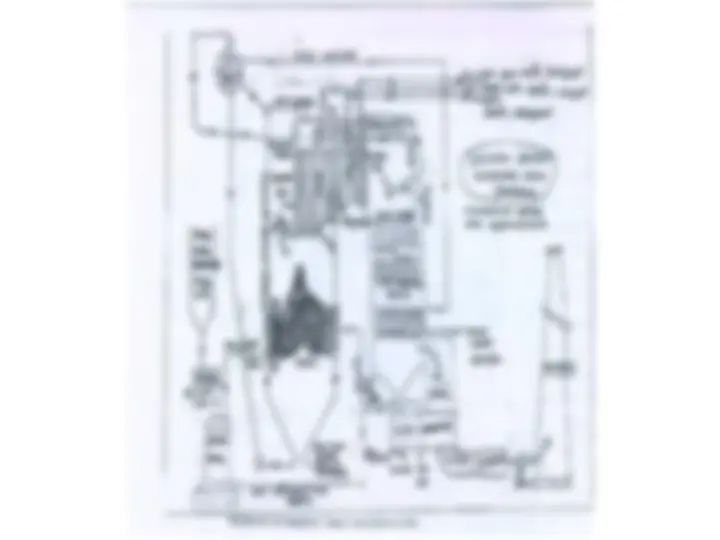

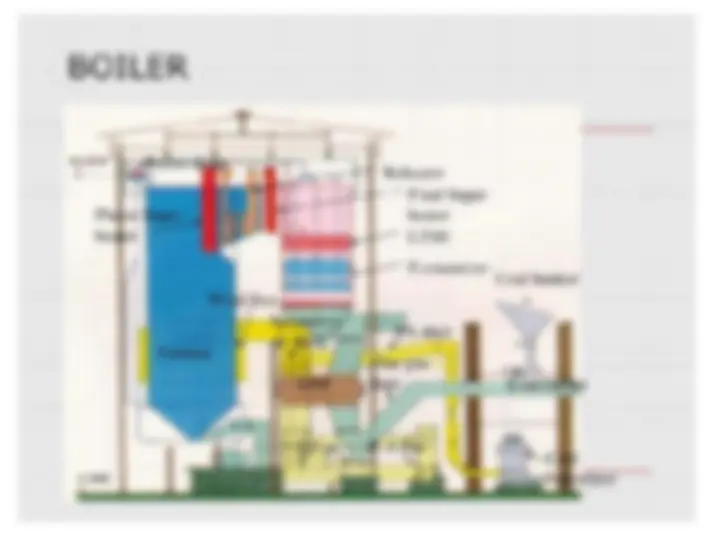

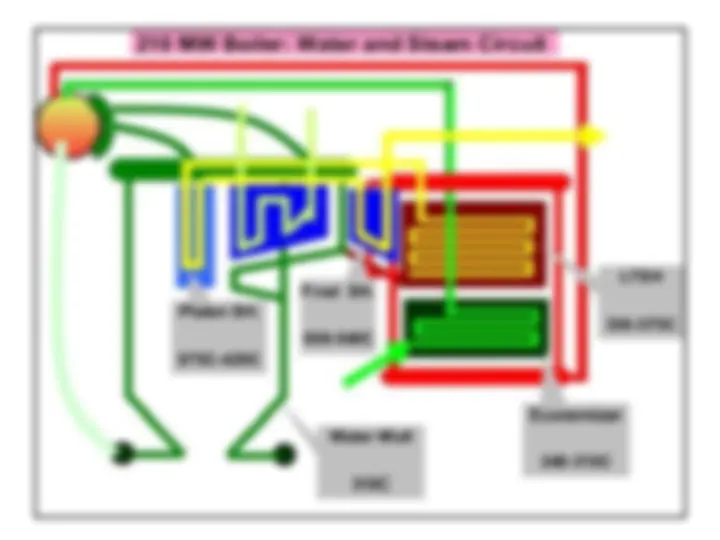

Boiler Construction :- Main parts of Boiler used in Thermal power plant Economizer, Boiler Drum, Down corners, Bottom Ring Header, Water wall, Primary, Superheater, Platen superheater, Final Superheater Reheater Coal firing nozzles, oil Firing nozzles, , Burners Windbox assembly, Igniters, Flame scanners and Soot Blowers. Figures on the next slide shows the basic construction of pulverised coal fired boilers.

Following selection factors are taken into consideration:- (^) Lowest capital cost, easy in construction, simplicity safety,

good working condition, easy in maintenance. (^) Availability of auxiliaries (^) Efficient operation, effective for heat transfer well insulate

casings, ability to deliver pure steam with effective drum internals, to generate steam of full capacity.

Boiler Construction :- Main parts of Boiler used in Thermal power plant Economizer, Boiler Drum, Down corners, Bottom Ring Header, Water wall, Primary, Superheater, Platen superheater, Final Superheater Reheater Coal firing nozzles, oil Firing nozzles, , Burners Windbox assembly, Igniters, Flame scanners and Soot Blowers. Figures on the next slide shows the basic construction of pulverised coal fired boilers.

The flue gas formed by combustion of a fuel in the furnace passes through the following passes

The flue gas formed by combustion of a fuel in the furnace passes through the following passes

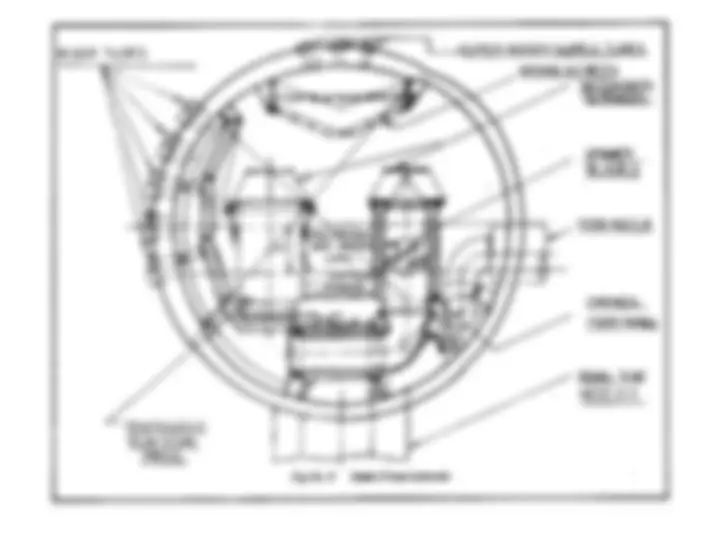

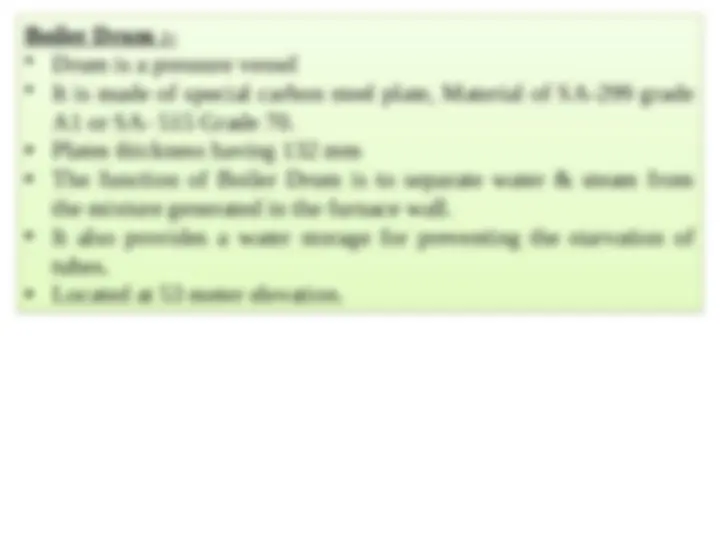

Boiler Drum :-

A1 or SA- 515 Grade 70.

Boiler Drum :-

A1 or SA- 515 Grade 70.

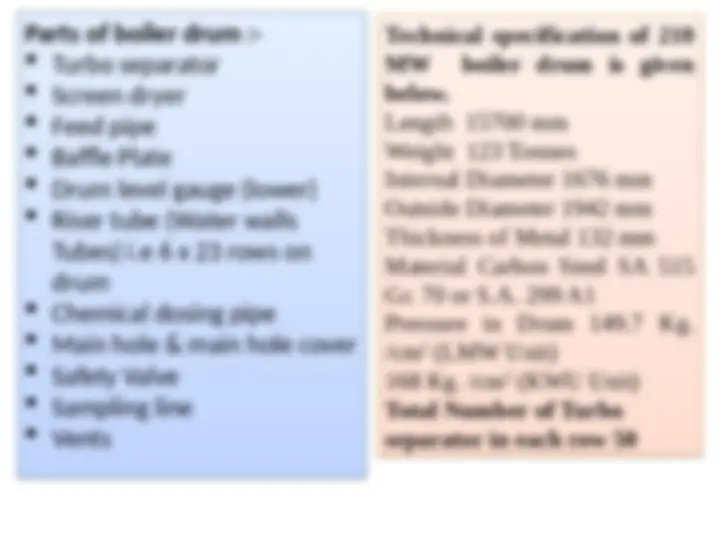

Technical specification of 210 MW boiler drum is given below. Length 15700 mm Weight 123 Tonnes Internal Diameter 1676 mm Outside Diameter 1942 mm Thickness of Metal 132 mm Material Carbon Steel SA 515 Gr. 70 or S.A. 299 A Pressure in Drum 149.7 Kg. /cm^2 (LMW Unit) 168 Kg. /cm^2 (KWU Unit) Total Number of Turbo separator in each row 50

Technical specification of 210 MW boiler drum is given below. Length 15700 mm Weight 123 Tonnes Internal Diameter 1676 mm Outside Diameter 1942 mm Thickness of Metal 132 mm Material Carbon Steel SA 515 Gr. 70 or S.A. 299 A Pressure in Drum 149.7 Kg. /cm^2 (LMW Unit) 168 Kg. /cm^2 (KWU Unit) Total Number of Turbo separator in each row 50